Product Function

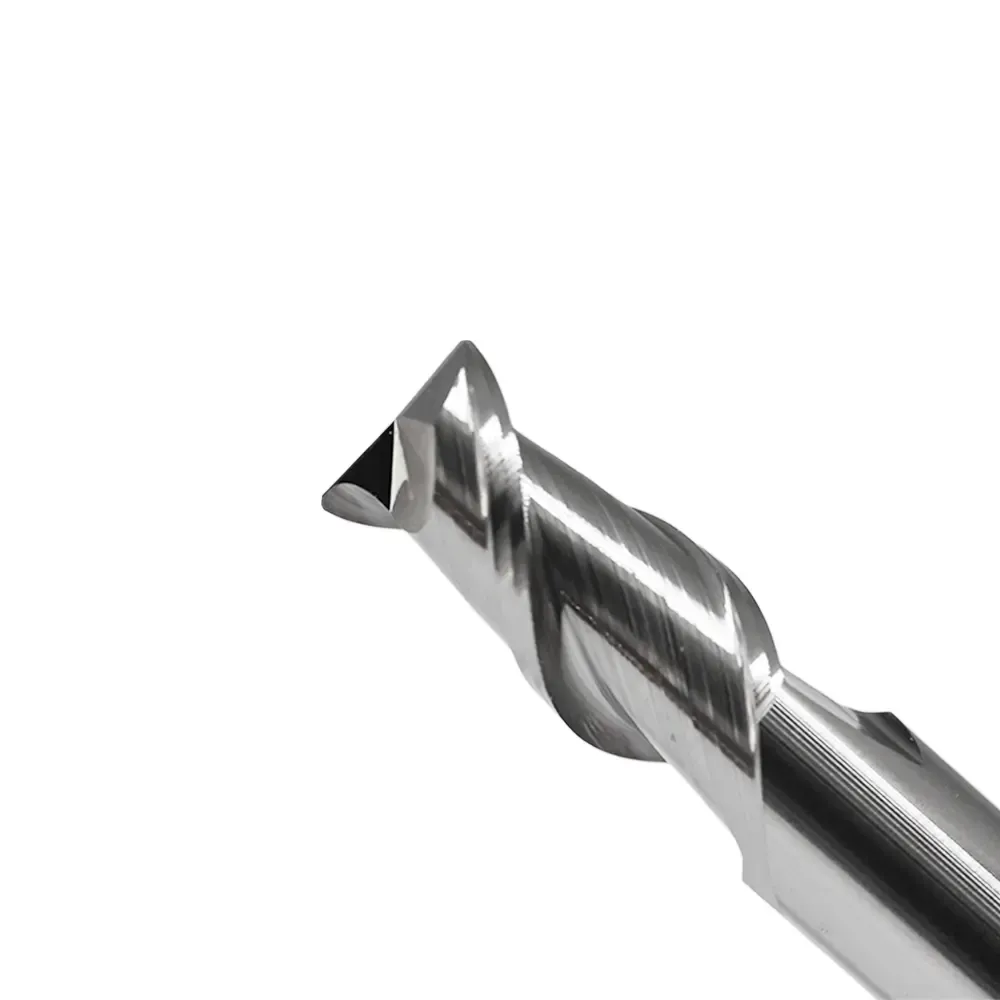

Our Tungsten Carbide Bull Nose End Mill 2 Flute for Aluminum is specifically engineered for high-speed, high-precision machining of non-ferrous materials. Designed with a micro-diameter geometry, this tool is the ultimate solution for:

- Precision Mold Making: Creating smooth curved surfaces and fillets in aluminum molds.

- 3C Electronic Components: Fine detail processing for phone cases, heat sinks, and delicate aluminum parts.

- Corner Strengthening: The bull nose (corner radius) design offers higher tool strength compared to square end mills, preventing chipping at the corners during high-speed cutting.

- Chip Evacuation: The 2-flute design with a large helix angle ensures rapid chip removal, preventing aluminum from sticking to the cutter (built-up edge).

Product Features

- Premium Material: Made from Ultra-Fine Micro Grain Tungsten Carbide (HRC55), offering exceptional wear resistance and hardness.

- Aluminum Specific Geometry:

- Polished Flutes: Mirror-like finish reduces friction and ensures smooth chip evacuation, critical for soft, gummy materials like aluminum.

- Reinforced Corner: The bull nose radius protects the cutting edge, extending tool life significantly compared to sharp corner tools.

- High Precision: Tolerance controlled within micro-levels, ensuring dimensional accuracy for intricate workpieces.

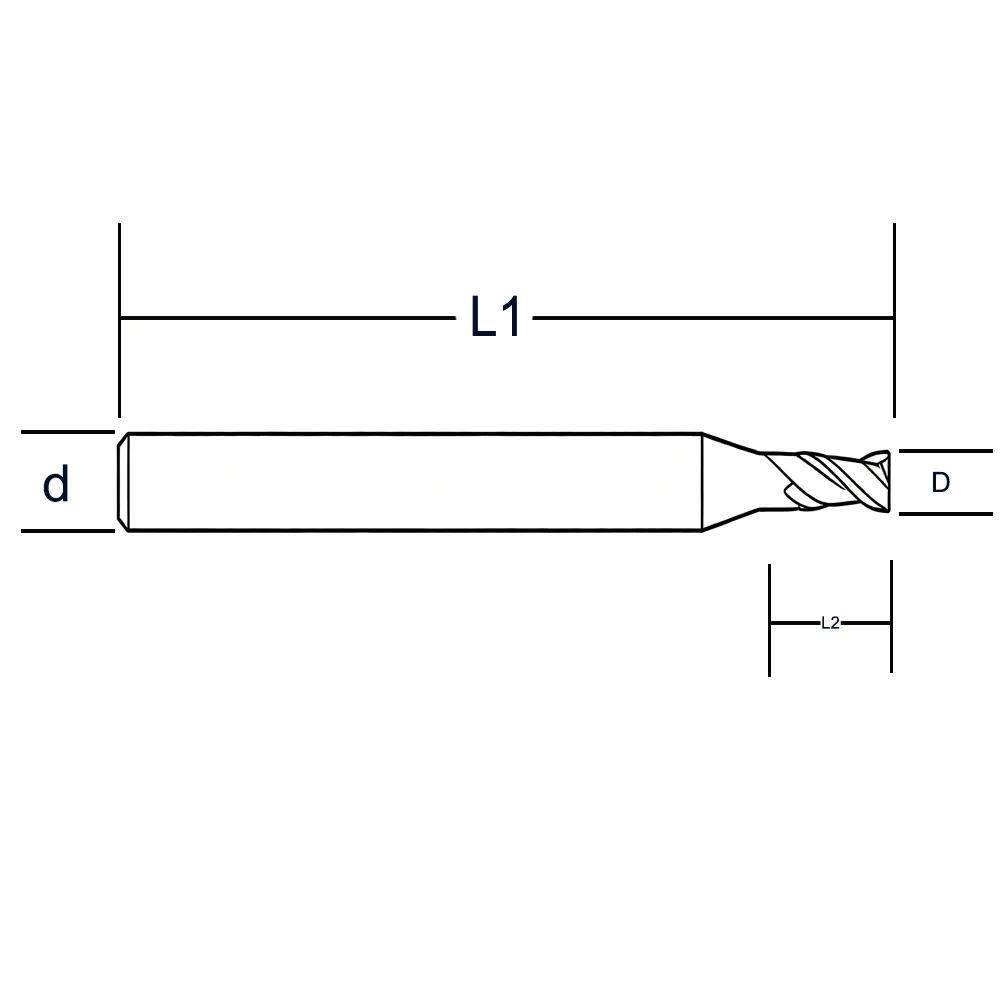

- Standard Shank: All micro cutter diameters feature a robust 4mm shank, providing stability and reducing vibration during machining.

Specifications

| | | | |

|---|

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | Reach: 2.5mm (Rib Processing/Necked) |

| | | | |

| | | | |

| | | | |

Note: Corner Radius (R) specifications can be customized upon request. Please contact sales for specific R sizes (e.g., R0.05, R0.1).

RPM/Feed Reference (Aluminum Machining)

For reference only. Adjust based on machine rigidity and cooling.

| | | |

|---|

ϕ0.3−ϕ0.4 | | | |

ϕ0.5−ϕ0.6 | | | |

ϕ0.8−ϕ1.0 | | | |

| | | |

- Coolant: Flood coolant or Oil Mist is highly recommended for Aluminum to prevent sticking.

Promotion Policy

We value every partnership and offer exclusive benefits to support your business:

- Free Sample: Free sample can be provided, if clients agree to pay for shipping cost.

- First Order Coupon: New clients can enjoy USD50 discount coupon for first order, if the total order amount is more than USD500.

- Big Order Discount: Clients can enjoy 2%~5% discount, if the total order amount is more than USD5000.

Client Benefits

Choosing us as your manufacturing partner guarantees:

- Direct Factory Pricing: No middlemen. You get the best price-to-performance ratio in the market.

- Quality Assurance: 100% inspection before shipment using advanced Zoller measuring equipment.

- Fast Dispatch: We maintain a healthy stock of standard micro sizes, ensuring quick turnaround times.

- Customization: Need a specific Corner Radius (R) or Neck Length? We offer OEM/ODM services tailored to your blueprints.

FAQ

Q1: Is this end mill suitable for Steel or Stainless Steel?

A1: This specific 2-flute design is optimized for Aluminum, Copper, and Plastics. For Steel or Stainless Steel, we recommend our 4-Flute AlTiN coated series.

Q2: What is the tolerance of the shank diameter?

A2: Our standard shank tolerance is h6 (0/-0.008mm), ensuring a perfect fit in high-precision collets.

Q3: Can I mix different sizes to reach the USD500 requirement for the coupon?

A3: Yes! You can mix any sizes and types of cutting tools in your first order to qualify for the USD50 discount.

Q4: How do you pack these micro end mills?

A4: Each micro end mill is individually packed in a robust plastic tube with foam protection to prevent damage to the delicate cutting edges during transit.