Product Function

Designed specifically for high-speed machining of non-ferrous materials, our 3 Flute Tungsten Carbide End Mill is the ultimate tool for milling Aluminum alloys, Copper, Brass, and Plastics.

The 3-flute geometry offers the perfect balance between chip evacuation space and core strength, making it ideal for:

- Slotting: Deep chip pockets allow for aggressive material removal rates (MRR).

- Side Milling / Profiling: Provides a superior surface finish.

- Plunging & Ramping: Excellent vertical cutting capabilities.

Product Features

- Mirror Polished Flutes: Our specialized grinding process creates an ultra-smooth flute surface. This significantly reduces friction and prevents "chip welding" or built-up edge (BUE), which is common when machining gummy aluminum.

- Premium Material: Manufactured from Ultra-Fine Micro Grain Tungsten Carbide, ensuring high wear resistance and long tool life even at high RPMs.

- Sharp Cutting Edge: A unique 45° helix angle and razor-sharp edge design reduce cutting forces, minimize vibration (chatter), and ensure a burr-free finish.

- Wide Range of Sizes: We offer precision increments (every 0.05mm/0.1mm) from diameter 1.05mm up to 11.9mm to meet your most specific CNC requirements.

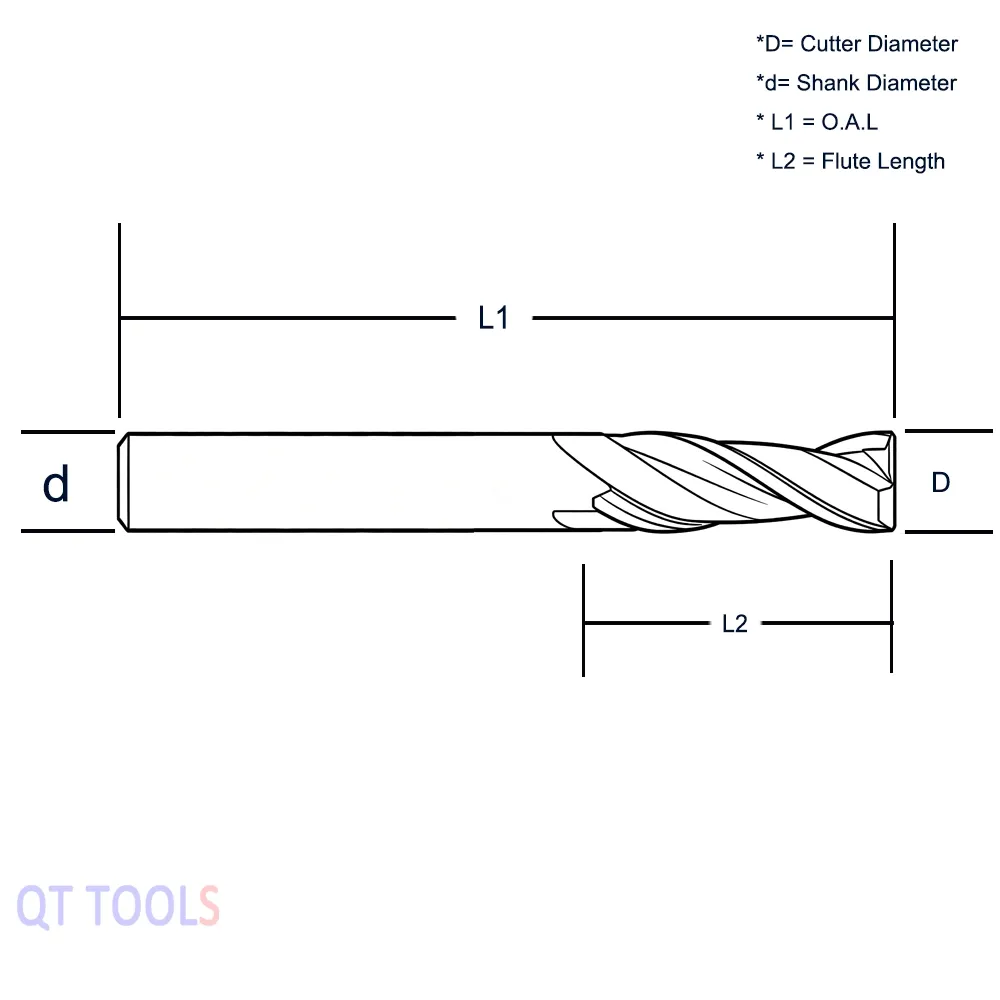

Specifications

Our inventory includes a comprehensive range of fractional and decimal sizes. The ratio of Flute Length (L2) to Cutter Diameter (D1) is optimized at 3:1 for deep reach applications.

| Cutter Diameter Range (D1) | | |

|---|

| | 3 x D1 (e.g., 3.15mm - 11.85mm) | |

| | 3 x D1 (e.g., 12.3mm - 17.7mm) | |

| | 3 x D1 (e.g., 18.3mm - 23.7mm) | |

| | 3 x D1 (e.g., 24.3mm - 29.7mm) | |

| | 3 x D1 (e.g., 30.3mm - 35.7mm) | |

> Note: We stock increments of 0.05mm and 0.1mm as shown in the datasheet. Custom dimensions are available upon request.

RPM/Feed Reference (Reference Only)

Recommended cutting parameters for Aluminum Alloys (e.g., 6061, 7075).

> Please adjust based on your machine rigidity, cooling system (Flood coolant recommended), and depth of cut.

Promotion Policy

To support our partners and new customers, we offer the following exclusive policies:

- Free Sample: Free sample can be provided, if clients agree to pay for shipping cost.

- First Order Coupon: New clients can enjoy USD 50 discount coupon for first order, if the total order amount is more than USD 500.

- Big Order Discount: Clients can enjoy 2%~5% discount, if the total order amount is more than USD 5000.

Client Benefits

- Factory Direct Pricing: Cut out the middleman. Get premium tools at manufacturer costs.

- Quality Assurance: 100% inspected by Zoller measuring devices before shipment.

- Fast Dispatch: Huge stock of standard sizes (as listed above) ready to ship within 24-48 hours.

- Technical Support: Access to our professional engineering team for machining advice and tool selection.

FAQ

Q1: Why use an uncoated (bright finish) end mill for Aluminum?

A: Aluminum is a soft, sticky material. Coatings like TiAlN can increase friction with aluminum, leading to chip welding. Our polished, uncoated carbide surface allows chips to slide off easily, ensuring a cleaner cut and longer tool life.

Q2: Can these tools cut other materials?

A: Yes! While optimized for Aluminum, they are also excellent for Brass, Copper, Bronze, Magnesium, and many plastics/acrylics.

Q3: What is the tolerance of your cutter diameter?

A: Our standard tolerance for cutter diameter is 0/-0.02mm, and shank tolerance is h6. High-precision options are available upon request.

Q4: Do you offer OEM/ODM services?

A: Yes, we can laser mark your logo on the shank and customize label packaging for your brand.