Product Function

Designed specifically for high-speed machining of non-ferrous materials, this 2-Flute Solid Carbide End Mill is the ultimate solution for precision milling of Aluminum, Aluminum Alloys (6061, 7075), Copper, Brass, and Plastics.

With cutter diameters ranging from 1.1mm to 3.9mm, this series is engineered for micro-milling applications, including:

- Precision slotting and profiling.

- 3C electronic component processing (phone cases, heat sinks).

- Fine detail engraving and contouring.

Product Features

Why choose our Aluminum Series End Mills?

- Mirror Polished Flutes: We utilize a specialized grinding process to achieve a mirror-like finish on the flutes. This significantly reduces friction, ensuring excellent chip evacuation and preventing the common "built-up edge" (sticking) problem when cutting aluminum.

- Premium Micro-Grain Carbide: Manufactured from ultra-fine tungsten carbide substrate, providing the perfect balance of hardness and toughness to resist breakage, even at small diameters.

- Specific Geometry for Aluminum: A sharp high-helix angle design cuts through soft materials effortlessly, leaving a burr-free, smooth surface finish.

- Vibration Absorption: The standardized 4mm shank provides rigid stability, reducing chatter during high-speed operations.

- High Tolerance: All diameters are ground to h6 tolerance standards, ensuring repeatability for CNC batch production.

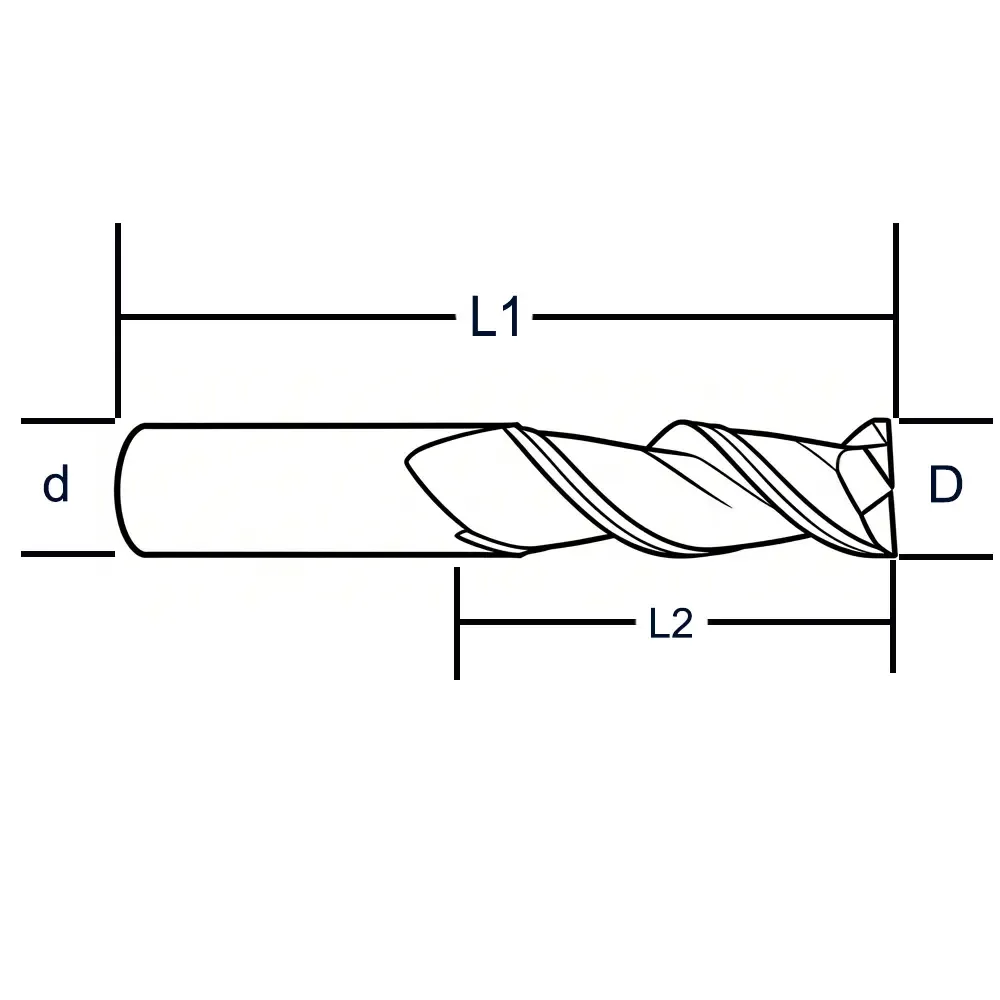

Specifications

RPM/Feed Reference Table (For Aluminum 6061/7075)

Note: These values are for reference. Please adjust based on your machine rigidity, cooling system, and specific depth of cut.

- Coolant Recommendation: Water-soluble coolant or MQL (Mist) is highly recommended to prevent chip welding.

Promotion Policy

- Free sample:Free sample can be provided, if clients agree to pay for shipping cost.

- First order coupon: New clients can enjoy USD50 discount coupon for first order, if the total order amount is more than USD500.

- Big order discount: Clients can enjoy 2%~5% discount, if the total order amount is more than USD5000.

Clients Benefits

Investing in our Micro Diameter Aluminum End Mills gives you:

- Reduced Scrap Rate: The sharp cutting edge prevents burrs, meaning fewer rejected parts.

- Higher Efficiency: High-speed machining capabilities allow you to run your CNC machines faster.

- Cost Savings: No need for post-machining polishing; the cut finish is often sufficient for final products.

- Versatility: One tool handles slotting, ramping, and profiling effectively.

FAQ

Q: Are these end mills coated?

A: Typically, these are Uncoated with a Bright/Polished Finish. For aluminum, coatings containing Aluminum (like AlTiN) can cause the material to stick to the tool. We recommend our Polished Uncoated carbide or optional DLC (Diamond-Like Carbon) coating upon custom request.

Q: Can I use this on Steel or Stainless Steel?

A: It is not recommended. The geometry and carbide grade are optimized for soft, non-ferrous materials. Using them on steel may result in premature chipping. Please check our "Steel Series" for those applications.

Q: What is the shank tolerance?

A: Standard h6 tolerance, suitable for high-precision shrink-fit holders and ER collets.

Q: Do you offer custom sizes not listed here?

A: Yes! As a manufacturer, we offer OEM/ODM services. If you need a specific length of cut or neck reach, please contact us for a quote.