Product Function

Designed for aggressive material removal, our Tungsten Carbide Roughing End Mill (4 Flute) is the ultimate tool for the "roughing" stage of CNC machining. Unlike standard end mills, the specialized wave-edge (corn teeth) geometry breaks metal chips into smaller pieces. This significantly reduces cutting forces, minimizes vibration, and allows for deeper cuts and faster feed rates on hardened steel (up to HRC55), preparing the workpiece efficiently for the final finishing pass.

Product Features

- Material: Premium Micro-Grain Solid Tungsten Carbide for superior wear resistance.

- Coating: Advanced AlTiN/TiAlN coating specifically for high-heat resistance during heavy milling on HRC55 steel.

- Geometry: 4-Flute design with a coarse pitch wave profile to maximize chip evacuation and heat dissipation.

- Application: Ideal for side milling, slotting, and cavity machining in Carbon Steel, Alloy Steel, Cast Iron, and Tool Steel.

- Precision: h6 shank tolerance ensures stable clamping and reduced runout.

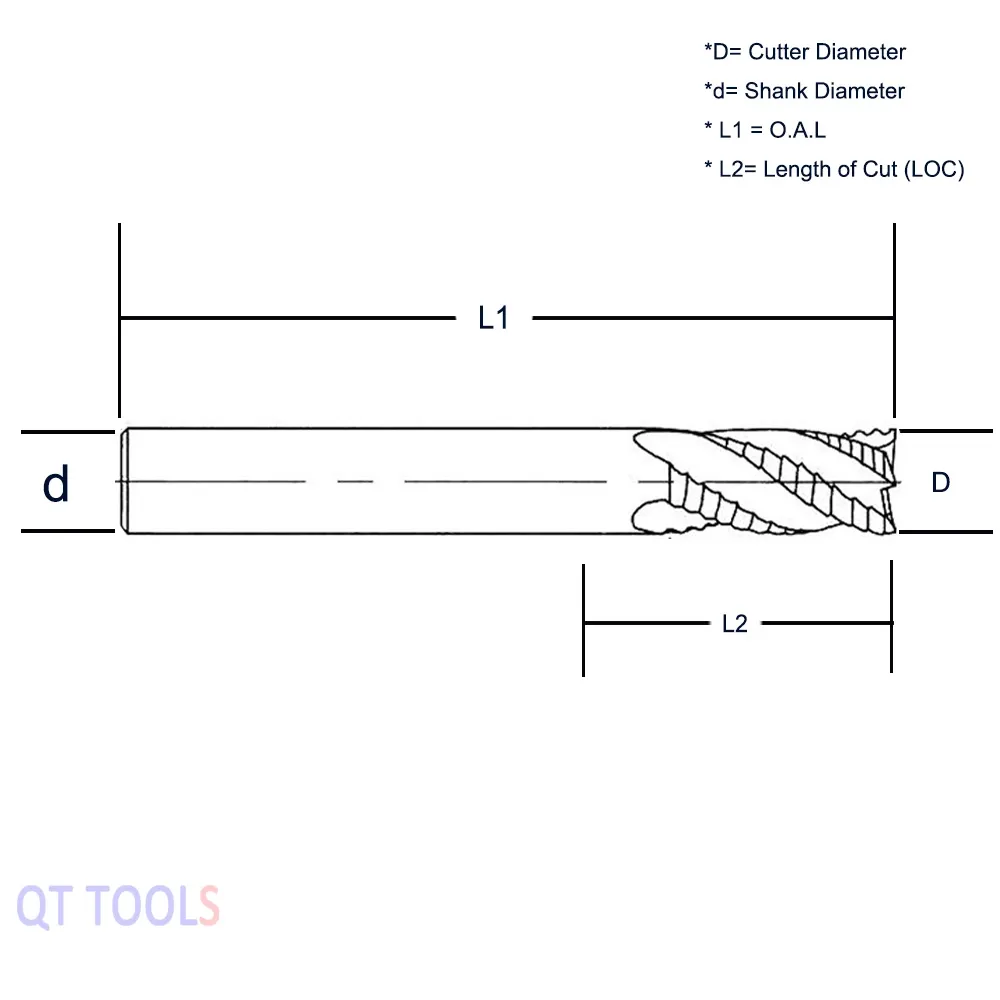

Specifications

Stock Availability: Ready to Ship

RPM/Feed Reference (For Steel HRC45-55)

Note: These are reference values. Adjust based on your machine rigidity and cooling system.

Promotion Policy

We value our partnership and offer exclusive benefits to support your business:

- Free Sample: Free sample can be provided, if clients agree to pay for shipping cost.

- First Order Coupon: New clients can enjoy USD50 discount coupon for first order, if the total order amount is more than USD500.

- Big Order Discount: Clients can enjoy 2%~5% discount, if the total order amount is more than USD5000.

Clients Benefits

- Factory Direct Pricing: Eliminate the middleman and get the best cost-per-part ratio.

- Consistent Quality: 100% inspection on geometry and runout before shipment.

- Fast Dispatch: With our extensive stock list (as shown in specs), most orders ship within 24-48 hours.

- Technical Support: Our engineering team is ready to assist with cutting parameters and tool selection.

FAQ

Q: Can this roughing end mill be used on Aluminum?

A: It is not recommended. This tool is coated and designed for ferrous metals (Steel, Cast Iron). For Aluminum, please check our Uncoated 3-Flute Aluminum Roughers to prevent chip welding.

Q: What is the helix angle of this cutter?

A: The standard helix angle for our HRC55 roughing end mills is 35° or 45°, optimized for chip removal in hard steel.

Q: Do you offer OEM/ODM services?

A: Yes, we can laser mark your logo on the shank and customize packaging for bulk orders.

Q: What is the shipping time for the US/Europe?

A: For stock items, we use DHL/FedEx/UPS, which typically takes 3-7 business days.