Product Function

Designed specifically for high-efficiency machining, our Tungsten Carbide 3 Flute Roughing End Mill is the ultimate tool for "hogging" out large amounts of material from Aluminum and non-ferrous metals.

Unlike standard finishing end mills, the unique "wave" or "corn teeth" profile on the cutting edge breaks chips into smaller, manageable pieces. This significantly reduces cutting forces and vibration, allowing for deeper cuts and faster feed rates without clogging the flutes. It is the primary choice for the roughing stage of CNC milling to maximize productivity before the final finish pass.

Product Features

- Specialized Geometry for Aluminum: The 3-flute design provides large chip pockets, ensuring excellent chip evacuation even at high material removal rates (MRR), preventing chip welding or packing.

- Wave Edge Design: The sinusoidal wave profile on the outer diameter breaks chips instantly, reducing spindle load and minimizing chatter.

- Premium Material: Manufactured from Ultra-Fine Micro Grain Tungsten Carbide, offering superior hardness and wear resistance.

- Polished Flutes: High-polish finish reduces friction and prevents aluminum from sticking to the cutter (Built-Up Edge).

- Versatility: Ideal for slotting, pocketing, and profiling in Aluminum alloys (6061, 7075), Copper, Brass, and other non-ferrous materials.

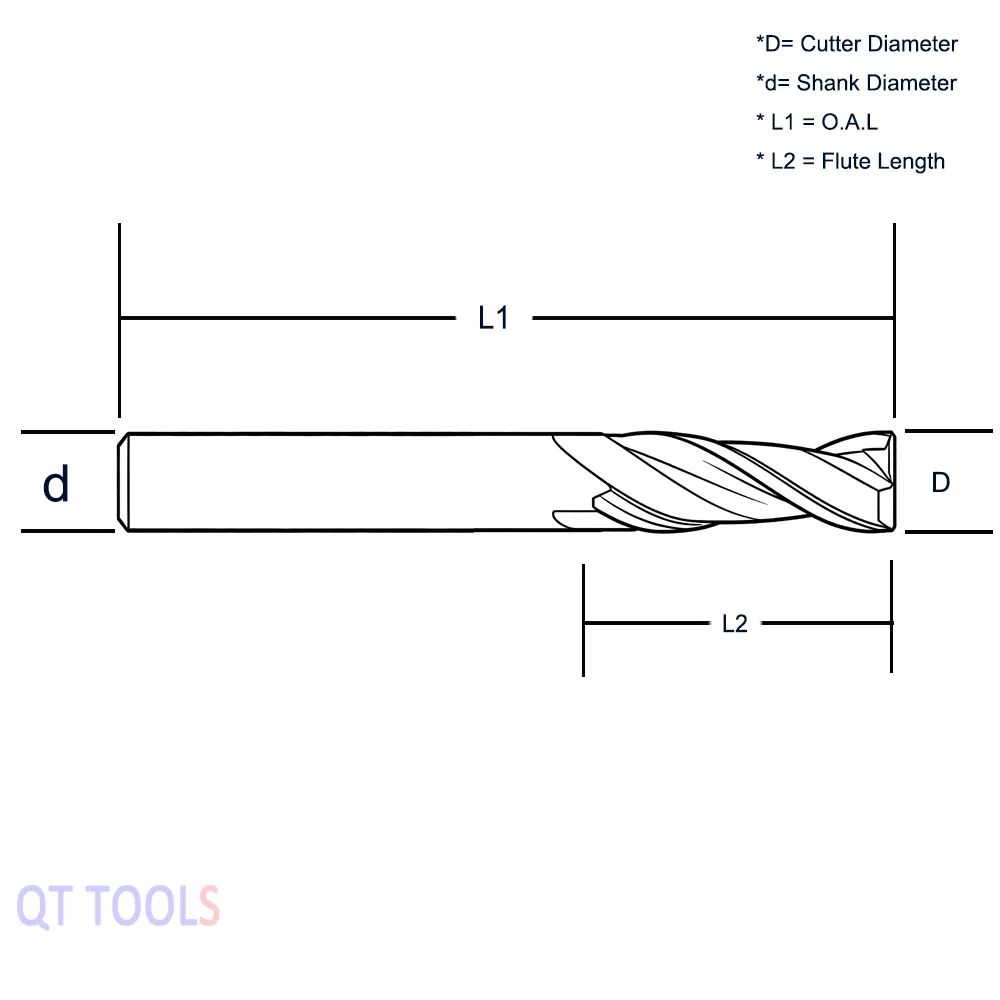

Specifications

We hold a massive stock of standard and long-series roughing end mills ready for immediate shipment.

RPM/Feed Reference (Recommended Parameters)

Note: These parameters are for reference only. Adjust based on your machine rigidity, cooling system, and specific aluminum grade.

Promotion Policy

We value every partnership and offer exclusive incentives to support your business growth:

- Free Sample: Free sample can be provided for testing, if clients agree to pay for the shipping cost.

- First Order Coupon: New clients can enjoy a USD 50 discount coupon for their first order, if the total order amount is more than USD 500.

- Big Order Discount: Clients can enjoy a 2%~5% discount, if the total order amount is more than USD 5000.

Clients Benefits

Choosing our tools means choosing reliability and profitability:

- Factory Direct Pricing: No middlemen. You get the best price-to-performance ratio in the market.

- Consistent Quality: Strict ISO quality control ensures every end mill performs identically, reducing machine downtime.

- Huge Inventory: As shown in the specification table, we stock a wide range of sizes (Standard & Extra Long) for same-day dispatch.

- Technical Support: Our engineering team is ready to assist with tool path optimization and parameter suggestions.

FAQ

Q1: Can this roughing end mill be used for Steel or Stainless Steel?

A: This specific 3-flute model is optimized for Aluminum and non-ferrous metals. For Steel or Stainless Steel, we recommend our 4-flute roughers with AlTiN coating. Please check our "Steel Series" category.

Q2: Do you offer coating for these aluminum roughers?

A: Standard stock is Uncoated/Polished to prevent sticking. However, we can provide DLC (Diamond-Like Carbon) or ZrN (Zirconium Nitride) coatings upon request for extended tool life in abrasive aluminum alloys.

Q3: What is the lead time for the items in the list?

A: All items listed in the specification table are in stock. Orders are typically shipped within 24-48 hours after payment confirmation.

Q4: Can you manufacture custom sizes not listed in the table?

A: Yes! We are a manufacturer. We can produce custom diameters, shank sizes, or overall lengths based on your drawings. The MOQ for custom tools is usually 10-50 pieces depending on the size.