Product Function

Designed specifically for non-ferrous materials, this 3 Flute Tungsten Carbide End Mill is the ultimate tool for high-speed machining of Aluminum Alloys (6061, 7075), Copper, Brass, and Plastics.

The unique geometry serves three main functions:

- High-Volume Slotting & Profiling: Capable of aggressive material removal rates (MRR) without clogging.

- Fine Finishing: The polished cutting edge produces a mirror-like surface finish on the workpiece, often eliminating the need for secondary polishing.

- Chip Management: The specialized U-Shape gullet ensures aluminum chips curl and evacuate immediately, preventing chip re-cutting and tool breakage.

Product Features

- Material: Premium Micro-Grain Tungsten Carbide (HRC55) for exceptional wear resistance and tool life.

- Geometry: U-Shape Design with a high helix angle (typically 45° or 55°). This deep valley design maximizes chip evacuation space.

- Surface Treatment: High Polished / Bright Finish. We grind the flutes to a mirror finish to reduce friction and prevent "Built-Up Edge" (aluminum sticking to the tool).

- Precision: Shank tolerance h6, ensuring tight run-out control for high-speed spindles (20,000+ RPM).

- Versatility: Suitable for Side Milling, End Milling, Slotting, and Ramp Milling.

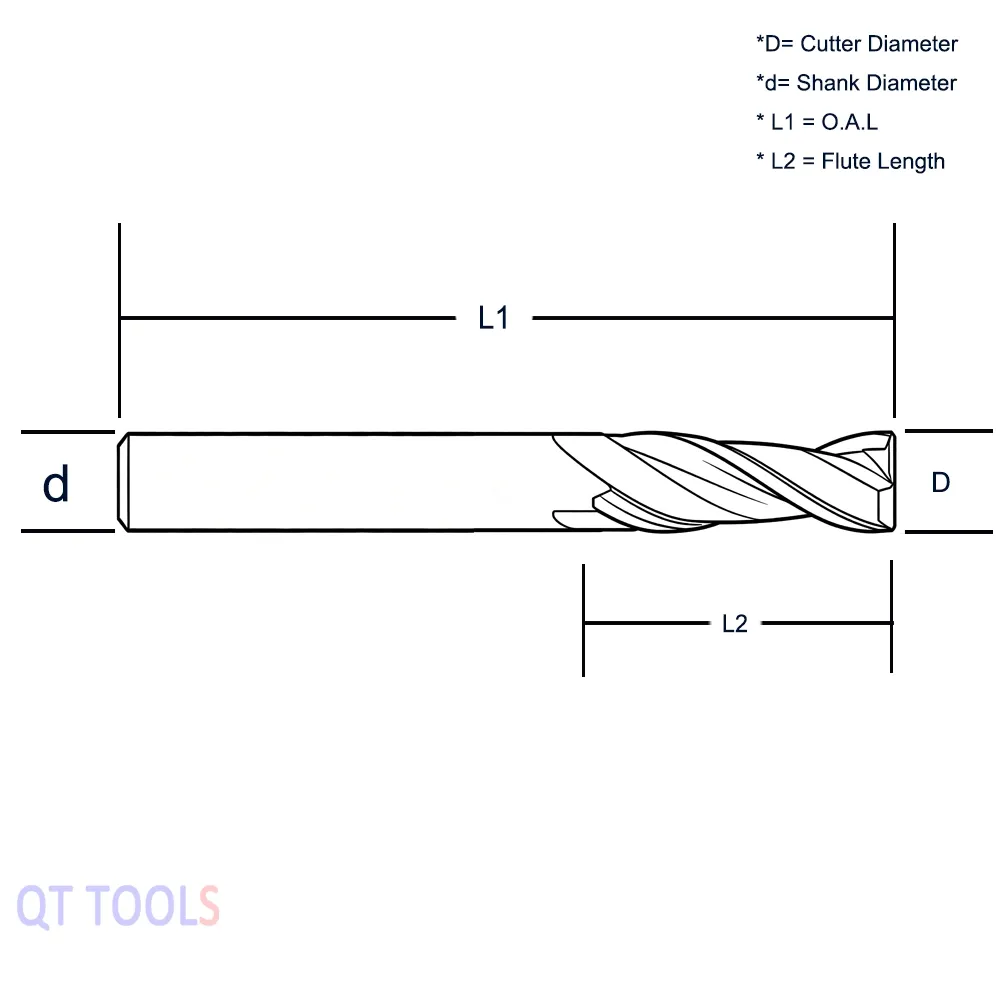

Specifications

Below is our standard stock list ranging from micro-diameters to heavy-duty sizes, including standard, long, and extra-long reach options.

| | | |

|---|

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | 10 / 12 / 14 / 16 / 18 / 20 | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

RPM/Feed Reference (General Aluminum Machining)

Note: These parameters are for reference. Adjust based on machine rigidity, cooling, and depth of cut.

Promotion Policy

We value our partnership and offer exclusive incentives for new and loyal customers:

- Free Sample: Free sample can be provided, if clients agree to pay for shipping cost.

- First Order Coupon: New clients can enjoy USD50 discount coupon for first order, if the total order amount is more than USD500.

- Big Order Discount: Clients can enjoy 2%~5% discount, if the total order amount is more than USD5000.

Clients Benefits

Why choose our Tungsten Carbide Tools?

- Factory Direct: No middleman. You get the best price-to-performance ratio in the market.

- Consistency: Our CNC grinding machines (Anca/Walter) ensure every batch meets the same strict tolerance.

- Inventory: We stock standard sizes (as listed above) for immediate shipment.

- Customization: Need a non-standard length or specific coating (like DLC)? We offer OEM/ODM services with low MOQs.

FAQ

Q1: Is this end mill suitable for steel?

A: No. This 3-flute U-shape design is optimized for Aluminum and Non-ferrous metals. For Steel, we recommend our 4-flute AlTiN coated series.

Q2: What is the advantage of the "U Shape"?

A: The U-shape flute provides a larger space for chip evacuation. Aluminum chips are sticky and voluminous; the U-shape prevents chips from packing inside the flute, which causes tool breakage.

Q3: Do you offer DLC (Diamond-Like Carbon) coating?

A: Yes! The standard version is Uncoated/Bright Finish (Polished), which is excellent for aluminum. However, for extended tool life in high-production environments, we can apply DLC coating upon request.

Q4: What is the shipping time?

A: Stock items ship within 24-48 hours. Large orders or custom specs typically take 7-10 days.

Q5: Can I mix sizes to reach the $500 coupon threshold?

A: Absolutely. You can mix any diameters or series (Standard/Long) to meet the promotion requirement.