Product Function

Our HRC55 4-Flute Solid Tungsten Carbide End Mills are engineered for high-performance CNC machining. They are specifically designed for:

- Side Milling & Face Milling: Excellent stability for peripheral milling applications.

- Slotting & Profiling: High rigidity design ensures vertical precision.

- Target Materials: Optimized for machining Carbon Steel, Alloy Steel, Cast Iron, and Pre-hardened Steel (up to HRC55).

- Applicable Machines: CNC Machining Centers, Engraving Machines, and High-speed CNC Lathes.

Product Features

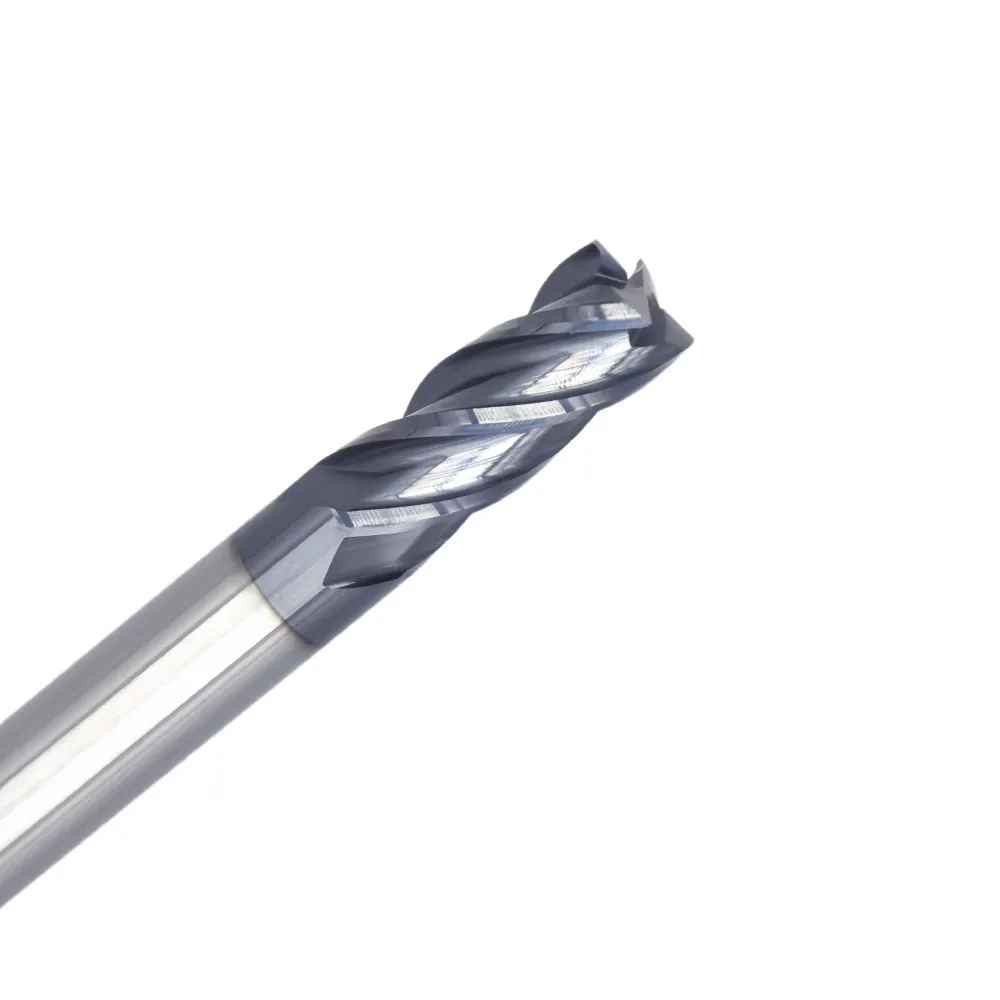

- Premium Material: Made from Ultra-Fine Micro Grain Tungsten Carbide, offering high toughness and heat resistance.

- Advanced Coating: AlTiN / TiSiN coating reduces friction and heat generation, extending tool life by up to 40% in dry machining.

- Spiral Angle: 35° (Optimized for chip evacuation and surface finish).

- Rigid Design: 4-flute geometry provides greater core strength, reducing tool deflection and vibration during heavy cutting.

- Wide Range: Available in micro sizes (1mm) up to heavy-duty sizes (20mm), including standard, long, and extra-long lengths.

Specifications

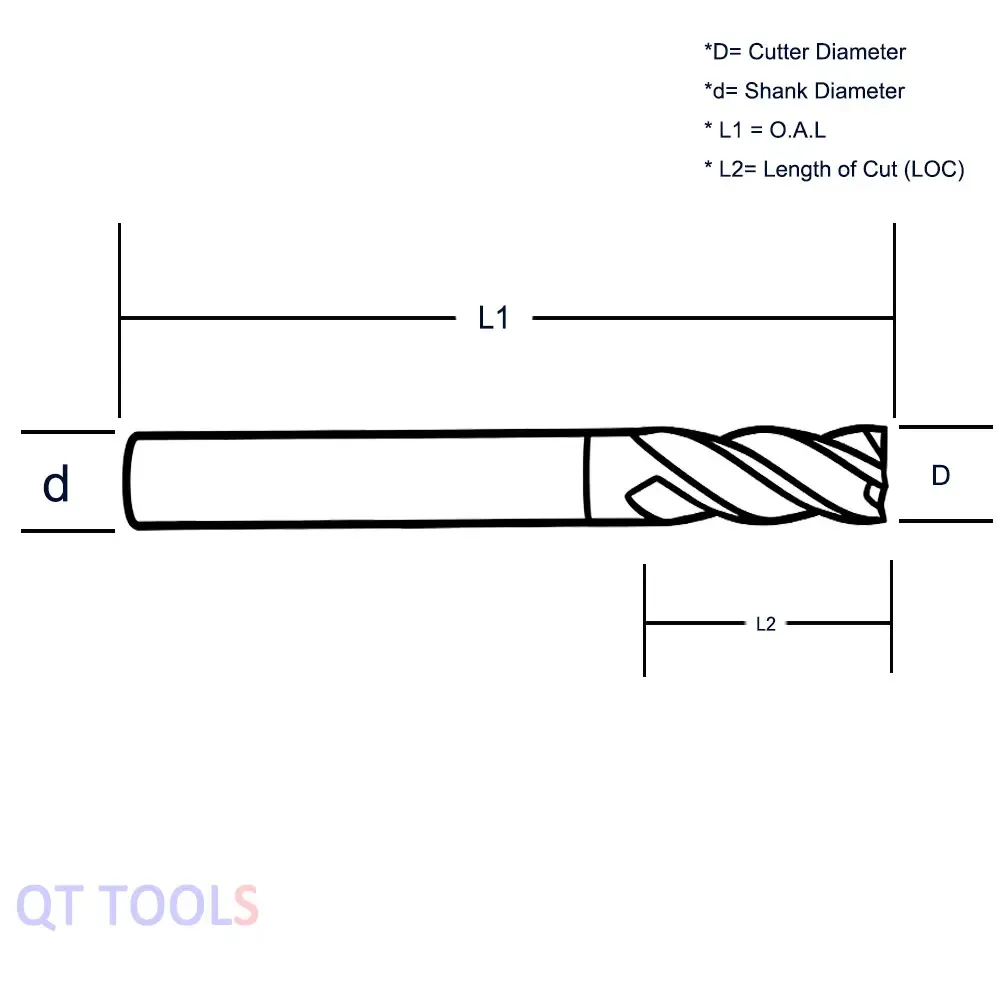

We provide a comprehensive range of dimensions to fit your specific machining needs.

Column Key:

- L2: Length of Cut / Flute Length (mm)

Standard Series (L1: 50mm - 75mm)

| | | |

|---|

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| 6.0 / 8.0 / 10.0 / 12.0 / 15.0 | | |

| | | |

| 8.0 / 10.0 / 12.0 / 14.0 / 20.0 | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

Long Reach & Extra Long Series (L1: 75mm - 100mm)

(Custom sizes are available upon request)

RPM/Feed Reference (Recommended Parameters)

Material: Carbon Steel / Alloy Steel (HRC < 45)

Note: Reduce Speed (RPM) and Feed by 20-30% for harder materials (HRC45-55).

Promotion Policy

We value our partnership and offer the following incentives to support your business:

- Free Sample: Free samples can be provided to verify quality, if clients agree to cover the shipping cost.

- First Order Coupon: New clients can enjoy a **USD

50discountcoupon∗∗fortheirfirstorder,providedthetotalorderamountexceedsUSD

- Big Order Discount: Clients can enjoy a 2% ~ 5% discount if the total order amount exceeds USD $5,000.

Client Benefits

Choosing our tungsten carbide tools gives you a competitive edge:

- Factory Direct Cost: Eliminate middlemen. Get the best price-performance ratio directly from the manufacturer.

- Consistent Quality: 100% inspection with advanced Zoller measuring equipment ensures every tool meets the specs.

- Fast Global Shipping: With our extensive stock of standard sizes (as listed above), we can ship standard orders within 24-48 hours.

- Technical Support: Our engineering team provides professional advice on cutting parameters and tool selection for your specific projects.

FAQ

Q1: What is the hardness rating for these end mills?

A: These end mills are designed for materials up to HRC55. We also manufacture HRC60, and HRC65 series upon request.

Q2: Can you produce custom sizes?

A: Yes, we offer OEM/ODM services. If you need a specific cutting length (L2) or shank diameter (D2) not listed in the standard table, please contact our sales team with your drawing or requirements.

Q3: What shipping methods do you use?

A: We partner with DHL, FedEx, UPS, and TNT for fast delivery. For large bulk orders, air or sea freight is available to save costs.

Q4: How do I claim the Free Sample?

A: Simply click the "Inquiry" button or email us. Let us know which size you need to test, and confirm your shipping address.