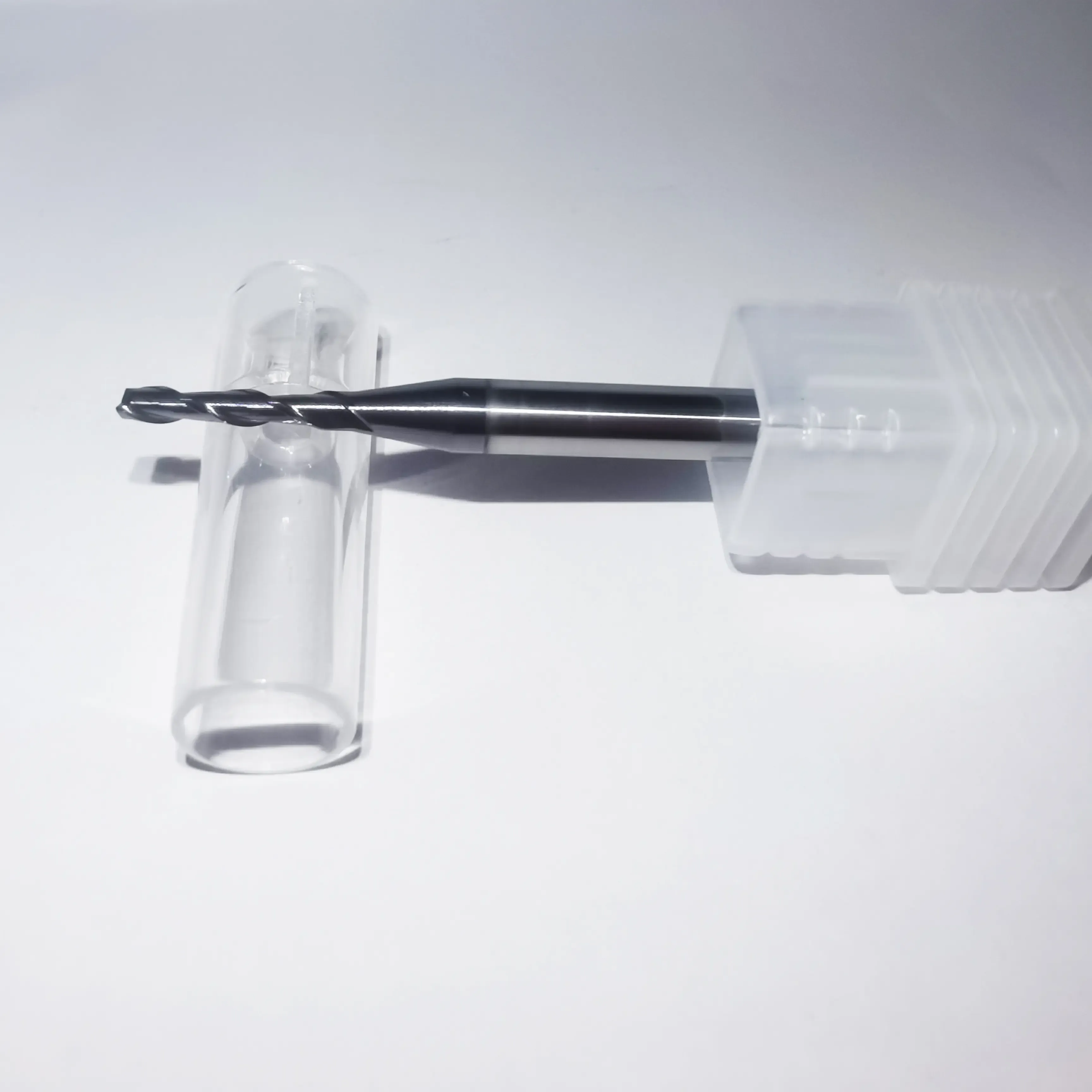

Extra Long Flute Tungsten Carbide Micro End Mill (For Steel HRC55)

Tackle deep slots and thick workpieces in a single pass with our Extra Long Cutting Length (Long Flute) Micro End Mills.

Unlike standard end mills or long-neck tools (where only the shank is relieved), this series features an extended cutting flute, allowing for continuous side milling and deep slotting without step-downs. Engineered with a rigid 4mm shank and AlTiN coating, it provides exceptional stability when machining Steel up to HRC55.

Key Features & SEO Benefits

- Extra Long Cutting Length (Up to 10xD): Flute lengths extend up to 10 times the cutter diameter (e.g., 1.0mm diameter with 10mm flute), enabling the machining of thick walls and deep layers.

- High Rigidity Design: Despite the long flute, the standard 4mm shank provides the necessary base rigidity to minimize deflection and chatter.

- AlTiN Coating for HRC55: Advanced coating technology ensures high heat resistance and extended tool life in Carbon Steel, Alloy Steel, and Cast Iron.

- 2-Flute Geometry: Optimized for chip evacuation in deep vertical cuts, preventing chip packing in deep slots.

Applications

- Deep Slotting: Cutting deep channels where chip evacuation from the entire depth is required.

- Side Milling (Profiling): Finishing tall vertical walls in a single pass to ensure a seamless surface finish (no step marks).

- General Steels: Suitable for P (Steel), M (Stainless), and K (Cast Iron) ISO materials.

Technical Specifications

Shank Diameter: 4.0mm (Standard h6 tolerance)

Coating: AlTiN (Black/Dark Grey)

Helix Angle: 35°

(Find your Cutter Diameter and select the required Flute Length L2)

| Available Cutting Lengths (L2)

(Multiple depth options available) | |

|---|

| | |

| | |

| 1.0, 1.5, 2.0, 2.5, 3.0 mm | |

| 1.5, 2.0, 2.5, 3.0, 3.5, 4.0 mm | |

| 1.5, 2.0, 2.5, 3.0, 3.5, 4.0, 4.5, 5.0 mm | |

| 2.0, 2.5, 3.0, 3.5, 4.0, 5.0 mm | |

| 2.0, 2.5, 3.0, 3.5, 4.0, 5.0 mm | |

| | |

| | |

| See 1.0mm or 1.2mm options | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

Usage Tips for Long Flute Tools

- Deflection Warning: Long flutes are more prone to deflection than standard tools. Reduce your feed rate (F) by 20-30% compared to standard length end mills.

- Stepover (Ae): For side milling with the full flute length, keep radial engagement (Ae) low (e.g., 5-10% of Diameter) to maintain accuracy.

Need a specific length not listed? We support OEM customization!