Product Function

Engineered specifically for Non-Ferrous Materials, this 2-Flute Solid Carbide Ball Nose End Mill features a specialized Mirror Polished flute surface. It is the ideal solution for high-speed 3D contouring and profiling of Aluminum Alloys (6061, 7075), Copper, Brass, and Plastics.

The "Decimal" Advantage:

This series offers a comprehensive range of Decimal Radii (e.g., R1.05, R1.18, R3.175). This is crucial for:

- Mold Making: Creating precise radii in shoe molds and bottle blowing molds without custom grinding.

- 3C Electronics: Machining complex curved surfaces on aluminum phone cases and heat sinks.

Product Features

- Mirror Polished Flutes: We utilize a unique grinding process to achieve a mirror-like finish. This minimizes friction and effectively prevents Built-Up Edge (BUE), ensuring chips slide off easily.

- Sharp Cutting Edge: Unlike steel tools which have honed edges, our aluminum series features a razor-sharp edge to shear through soft materials cleanly, leaving a burr-free surface.

- Deep Gullet Design: The 2-flute geometry provides maximum chip space, allowing for high feed rates and efficient chip evacuation during deep cavity milling.

- Uncoated / Bright Finish: Typically supplied uncoated to maintain the sharpest possible edge. (DLC - Diamond-Like Carbon coating available upon request for extreme wear resistance).

- Wide Size Range: From micro R1.05 to R4.5, covering all your precision detailing needs.

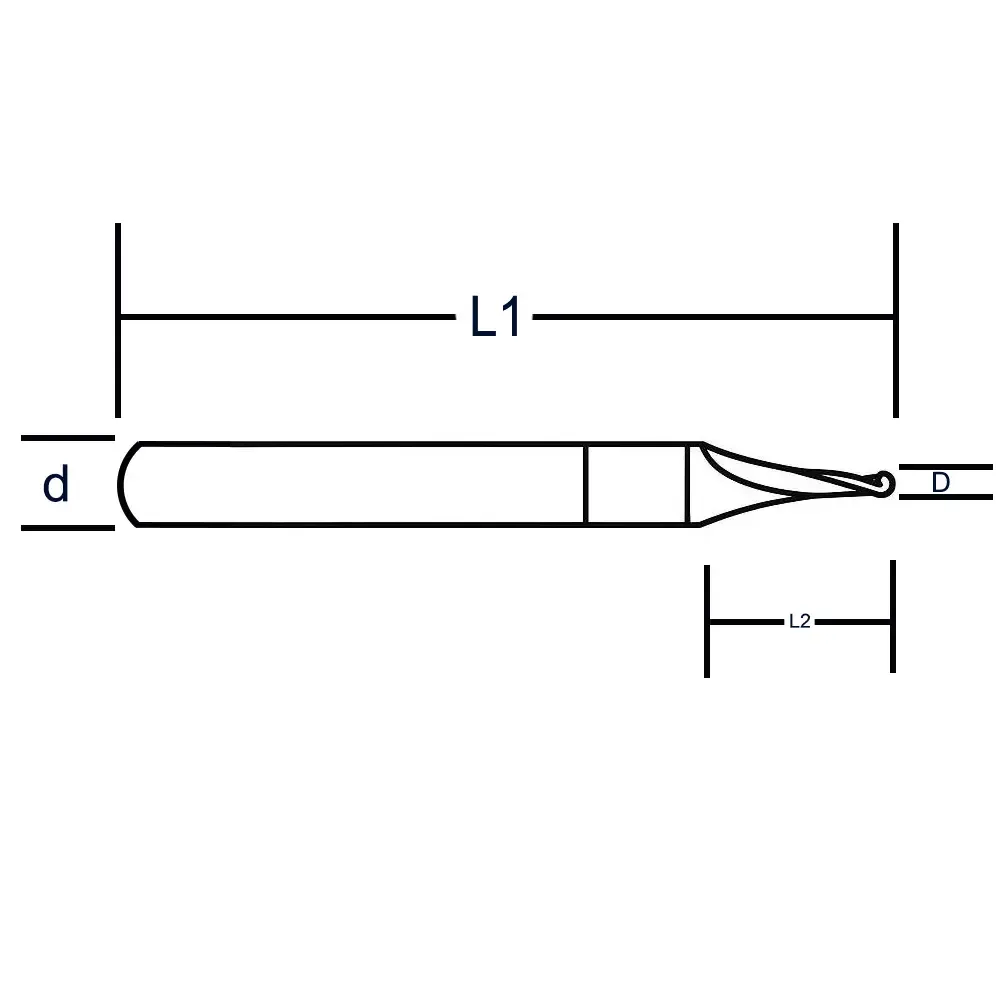

Specifications

RPM/Feed Reference Table (For Aluminum Alloys)

Note: Aluminum allows for much higher speeds than steel. High RPM is recommended to achieve a glossy surface finish.

- Coolant Strategy: Flood Coolant (Water-soluble oil) is highly recommended to flush chips and keep the tool cool. MQL (Mist) is also effective.

Promotion Policy

We support our partners with flexible policies to lower your trial cost:

- Free Sample: We are confident in our quality. A Free Sample can be provided for testing (clients only need to cover the shipping cost).

- First Order Coupon: New clients can enjoy a **USD

50DiscountCoupon∗∗fortheirfirstorder,providedthetotalorderamountexceedsUSD

- Big Order Discount: For bulk purchases, clients can enjoy a 2% ~ 5% Discount if the total order amount exceeds USD $5000.

Clients Benefits

- Mirror Finish: The polished flutes produce a surface finish on the workpiece that often requires no manual polishing.

- No Sticking: Say goodbye to "gummy" aluminum sticking to your tool and ruining the part.

- Inventory Ready: We stock the decimal sizes (e.g., R1.18) that usually require 2-week lead times from other suppliers.

FAQ

Q: Are these tools coated?

A: No, they are Uncoated and Mirror Polished. This is the standard for Aluminum to ensure the sharpest cutting edge. If you need DLC (Diamond-Like Carbon) coating for extended life in abrasive aluminum, please contact us for a custom quote.

Q: Can I use this on Acrylic or Plastics?

A: Yes! The sharp edge and polished flute make this tool excellent for Acrylic (PMMA), Polycarbonate, and other plastics, leaving a clear, transparent finish.

Q: Is R3.175 compatible with 1/8" collets?

A: The cutting radius is R3.175 (1/8"), but please note the shank diameter is 8mm. You will need an 8mm collet to hold this tool.

Q: What is the runout tolerance?

A: We guarantee a runout of less than 0.005mm to ensure balanced cutting at high RPMs.