Product Function

The 3 Flute Tungsten Carbide End Mill for Aluminum is the "Goldilocks" tool for non-ferrous machining, bridging the gap between 2-flute and 4-flute designs.

- Vibration Reduction: The 3-flute geometry provides better core strength than a 2-flute mill, significantly reducing chatter and vibration during high-speed machining.

- Superior Surface Finish: With more cutting edges per revolution, it delivers a finer wall and floor finish, often eliminating the need for a separate finishing pass.

- Deep Pocketing & Slotting: Our Extra Long Series (up to 200mm) allows for deep cavity machining where standard tools cannot reach, maintaining rigidity without rubbing.

- Efficient Chip Evacuation: Large, polished gullets ensure that despite having an extra flute, chips are evacuated rapidly to prevent re-cutting or clogging.

Product Features

- Material: Ultra-Fine Micro Grain Tungsten Carbide (HRC55) for high wear resistance.

- Uncoated & Polished: Specialized mirror-like polish on the flutes minimizes friction and prevents "Built-Up Edge" (BUE) where aluminum sticks to the tool.

- Helix Angle: 45° or 55° high helix design for smooth shearing action and vertical chip ejection.

- Lengths: From standard 50mm up to 200mm Extra Long for deep mold making and aerospace parts.

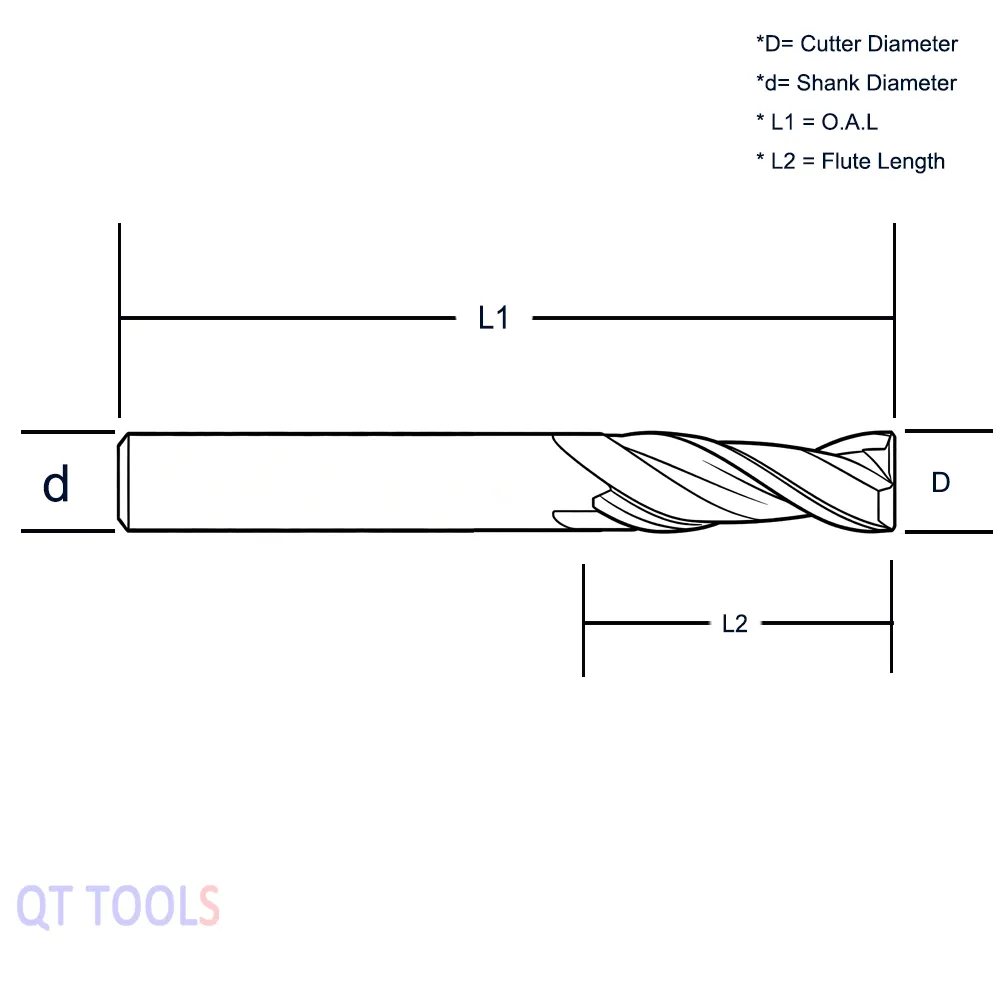

- Shank Options: Standard straight shank with h6 tolerance for high-precision collets.

Specifications

We offer an extensive range of sizes. Below is the specification chart for our Standard and Long Series.

RPM/Feed Reference (Aluminum Alloys)

Note: 3-Flute end mills allow for higher feed rates compared to 2-flute mills. Always adjust based on your machine's rigidity and cooling capabilities.

| | | | |

|---|

| | | | |

| | | | |

ϕ8−10mm | | | | |

ϕ12−16mm | | | | |

- Coolant: Flood coolant is strongly recommended to flush chips and maintain temperature.

- Long Reach Tools: Reduce RPM and Feed by 30-50% when using tools with OAL > 100mm to prevent vibration.

Promotion Policy

- Free Sample: Free sample can be provided, if clients agree to pay for shipping cost.

- First Order Coupon: New clients can enjoy USD50 discount coupon for first order, if the total order amount is more than USD500.

- Big Order Discount: Clients can enjoy 2%~5% discount, if the total order amount is more than USD5000.

Client Benefits

- Extended Reach Capabilities: Our stock of 100mm, 150mm, and 200mm end mills allows you to take on deep-mold jobs without waiting for custom tooling.

- Cost Efficiency: 3-Flute design offers longer tool life than 2-flute in stable setups, reducing tool change frequency.

- Consistency: CNC ground ensures every flute cuts equally, providing excellent surface finishes straight off the machine.

- Fast Shipping: Large inventory of standard and non-standard lengths ready for immediate dispatch.

FAQ

Q1: Why choose a 3-flute end mill over a 2-flute for Aluminum?

A1: While 2-flute is great for chip evacuation in deep slots, the 3-flute design offers a stronger core and better balance. This allows for higher feed rates and a smoother surface finish, especially in peripheral milling.

Q2: Are these tools coated?

A2: Standard specification is Uncoated High Polish. Coatings can sometimes increase friction in aluminum. However, we can provide DLC (Diamond-Like Carbon) or ZrN coatings upon request for abrasive aluminum alloys (high silicon).

Q3: Can I use the 150mm/200mm long end mills at full speed?

A3: For extended length tools (Over All Length > 100mm), we recommend reducing the RPM and Feed Rate initially to avoid chatter, then ramping up as stability allows.

Q4: Do you offer mixed size orders for the bulk discount?

A4: Yes, you can combine different diameters and lengths (e.g., standard lengths mixed with 150mm long series) to reach the order value required for discounts.