Product Function

Designed specifically for high-speed machining of non-ferrous metals, our 3 Flute Tungsten Carbide End Mill with Long Cutting Length is the ultimate solution for deep slotting and profiling in Aluminum alloys (6061, 7075), Copper, and Brass.

The unique 3-flute geometry balances large chip evacuation space with core strength, allowing for deep passes without clogging. This tool is engineered to solve the common issue of "chip welding" or sticking when machining aluminum, ensuring a mirror-like surface finish on your workpieces.

Product Features

- Extended Reach Capability: Features an extra-long flute length (up to 5x-9x diameter ratio), perfect for deep pocketing and wall finishing where standard end mills fail.

- Mirror Polished Flutes: Special grinding process reduces friction and heat generation, effectively preventing built-up edge (BUE) and chip packing.

- High-Quality Material: Made from Ultra-Fine Micro Grain Tungsten Carbide (HRC55), offering superior wear resistance and tool life compared to HSS or standard carbide.

- Vibration Control: Optimized helix angle reduces chatter during deep cutting operations, ensuring dimensional accuracy.

- Universal Shank: All sizes from 1mm to 4mm cutter diameter come with a robust 4mm shank, providing extra stability and compatibility with standard collets.

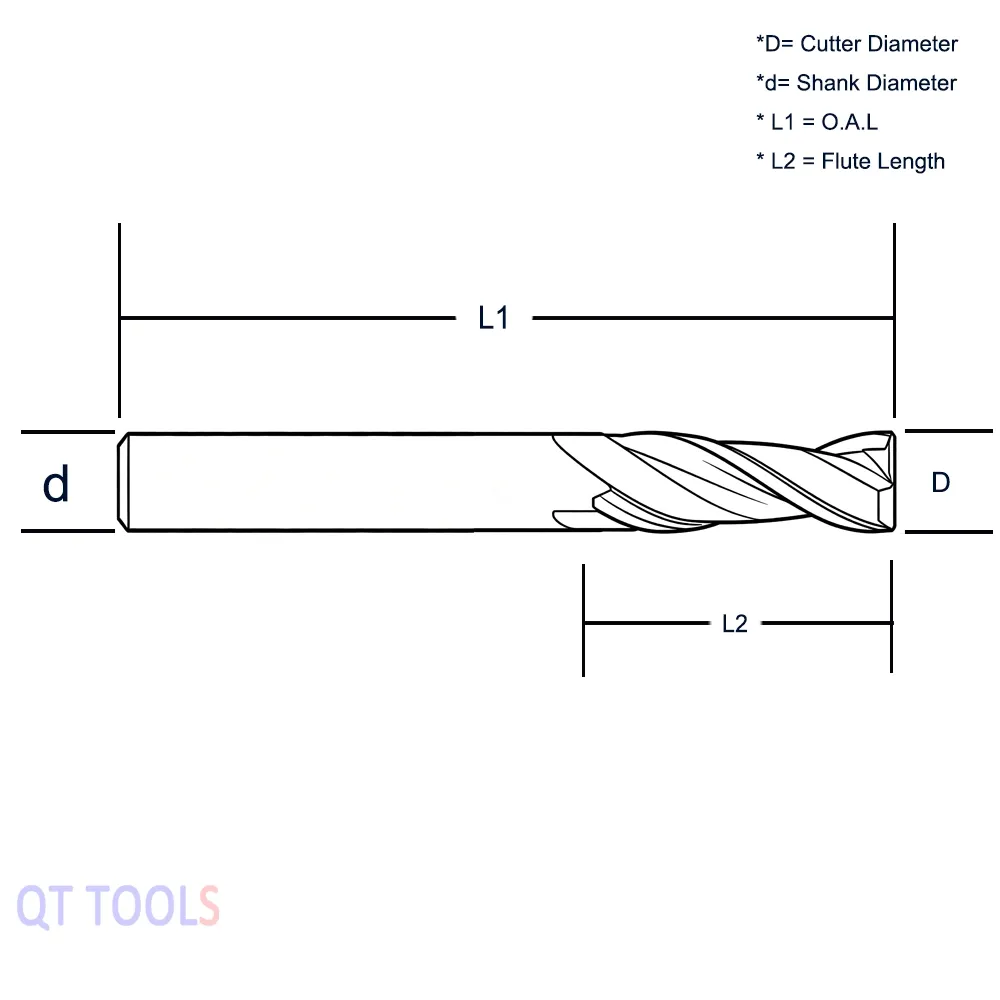

Specifications

Stock Status: In Stock (Ready to Ship)

Material: Solid Tungsten Carbide

Coating: Uncoated (Polished for Aluminum)

Flutes: 3 Flutes

Helix Angle: 45°

| | | |

|---|

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | 10 / 12 / 14 / 15 / 16 / 18 | |

| | | |

| | | |

RPM/Feed (Reference Parameters)

Note: These parameters are for reference only. Adjust based on your machine rigidity, cooling system, and specific aluminum grade.

Coolant Recommendation: Flood coolant or MQL (Mist) is highly recommended to prevent chip sticking.

Promotion Policy

We value our partnership and offer exclusive benefits to support your business:

- Free Sample: We are confident in our quality. A Free Sample can be provided for testing if you agree to cover the shipping cost.

- First Order Coupon: New clients enjoy a **USD

50discountcoupon∗∗fortheirfirstorder(Minimumorderamount:USD

- Big Order Discount: Scale your business with us. Clients enjoy a 2%~5% discount for total order amounts exceeding USD $5,000.

Client Benefits

- Factory Direct Pricing: No middlemen. You get the best price-to-performance ratio in the market.

- Consistent Quality: Manufactured on top-tier 5-Axis CNC grinders with strict quality control.

- Fast Shipping: All specifications listed above are In Stock. We typically ship within 24-48 hours.

- Technical Support: Our team of engineers is ready to assist you with cutting parameters and tool selection.

FAQ

Q: Can these end mills be used on Steel or Stainless Steel?

A: While they are tough, the geometry is optimized for Aluminum. Using them on steel may result in premature wear. We have a dedicated series for Steel/Stainless Steel—please check our catalog.

Q: Do you offer custom sizes not listed in the table?

A: Yes! As a manufacturer, we offer OEM/ODM services. If you need a specific length of cut or overall length, please contact our sales team for a quote.

Q: How do you pack the tools?

A: Each end mill is packed in a robust plastic tube with label protection to ensure it arrives safely.