Boost aluminum machining with our 3-Flute DLC Coated Carbide End Mills. U-Shape design prevents chip sticking. Factory direct price & Free Samples available!

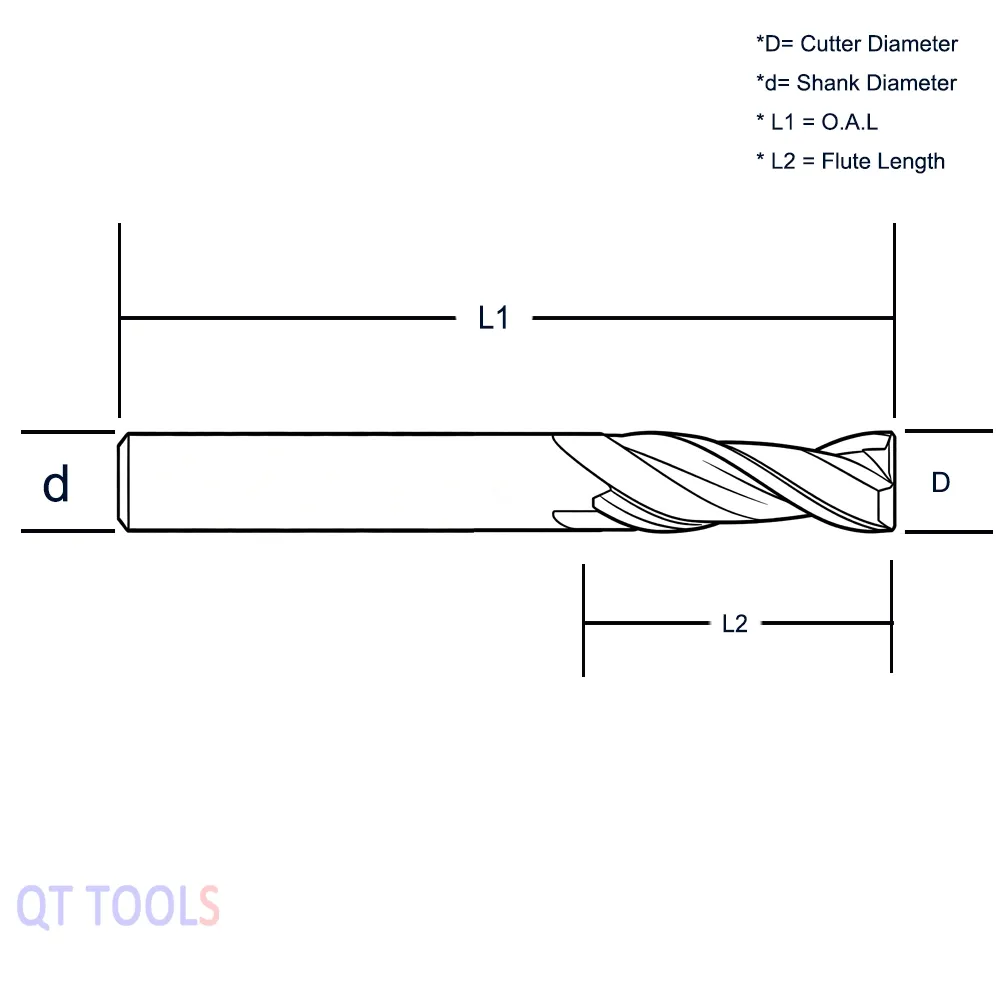

Cutter Diameter (D1) | Shank Diameter (D2) | Length of Cut (L2) | Over All Length (L1) |

|---|---|---|---|

Standard Length Series | | | |

1.0mm | 4mm | 1 / 2 / 3mm | 50mm |

1.5mm | 4mm | 2 / 3 / 4.5mm | 50mm |

2.0mm | 4mm | 2 / 3 / 4 / 6mm | 50mm |

2.5mm | 4mm | 3 / 4 / 5 / 7.5mm | 50mm |

3.0mm | 3mm | 9mm | 50mm |

3.0mm | 4mm | 3 / 4 / 6 / 9mm | 50mm |

3.0mm | 6mm | 9mm | 50mm |

4.0mm | 4mm | 4 / 6 / 8 / 12mm | 50mm |

4.0mm | 6mm | 12mm | 50mm |

5.0mm | 5mm | 15mm | 50mm |

5.0mm | 6mm | 15mm | 50mm |

5.0mm | 6mm | 20mm | 60mm |

6.0mm | 6mm | 6 / 8 / 10 / 12 / 18mm | 50mm |

6.0mm | 6mm | 20mm | 60mm |

6.5mm | 8mm | 19.5mm | 60mm |

7.0mm | 8mm | 21mm | 60mm |

7.5mm | 8mm | 22.5mm | 60mm |

8.0mm | 8mm | 8 / 10 / 12 / 14 / 24mm | 50mm |

10.0mm | 10mm | 10 / 12 / 14 / 16 / 18 / 20mm | 60mm |

10.0mm | 10mm | 30mm | 75mm |

11.0mm | 12mm | 33mm | 75mm |

12.0mm | 12mm | 12 / 14 / 16 / 18 / 20mm | 60mm |

12.0mm | 12mm | 36mm | 75mm |

Long Flute / Long Shank Series | | | |

1.0mm | 4mm | 3mm | 75mm / 100mm |

1.5mm | 4mm | 4.5mm | 75mm / 100mm |

2.0mm | 4mm | 6mm | 75mm / 100mm |

2.5mm | 4mm | 7.5mm | 75mm / 100mm |

3.0mm | 3mm | 9mm | 75mm / 100mm |

3.0mm | 4mm | 9mm | 75mm / 100mm |

4.0mm | 4mm | 14 / 16mm | 75mm |

4.0mm | 4mm | 20 / 25 / 30mm | 100mm |

5.0mm | 6mm | 25mm | 75mm |

5.0mm | 6mm | 30mm | 100mm |

6.0mm | 6mm | 25 / 30mm | 75mm |

6.0mm | 6mm | 25 / 40mm | 100mm |

6.0mm | 6mm | 45mm | 150mm |

8.0mm | 8mm | 32mm | 75mm |

8.0mm | 8mm | 35 / 40mm | 100mm |

8.0mm | 8mm | 50mm | 150mm |

10.0mm | 10mm | 40mm | 100mm |

10.0mm | 10mm | 55mm | 150mm |

12.0mm | 12mm | 45mm | 100mm |

12.0mm | 12mm | 60mm | 150mm |

16.0mm | 16mm | 45mm | 100mm |

16.0mm | 16mm | 70mm | 150mm |

16.0mm | 16mm | 90mm | 200mm |

Diameter (mm) | RPM | Feed Rate (mm/min) | a_p (Axial Depth) | a_e (Radial Depth) |

|---|---|---|---|---|

1.0 - 3.0 | 12,000 - 24,000 | 300 - 1,200 | 0.2D - 0.5D | 0.1D - 0.4D |

4.0 - 6.0 | 8,000 - 18,000 | 1,000 - 2,500 | 0.5D - 1.0D | 0.2D - 0.5D |

8.0 - 12.0 | 6,000 - 12,000 | 2,000 - 4,500 | 0.5D - 1.0D | 0.3D - 0.6D |

16.0+ | 3,000 - 8,000 | 2,000 - 4,000 | 0.5D - 1.0D | 0.3D - 0.7D |