Product Function

Designed specifically for high-speed machining of non-ferrous materials, this Tungsten Carbide Bull Nose End Mill (3 Flute) is the ultimate tool for milling Aluminum, Aluminum Alloys, Copper, and Brass.

The "Bull Nose" geometry (Corner Radius) provides greater corner strength compared to square end mills, preventing chipping and extending tool life, while producing a superior surface finish compared to ball nose mills on flat surfaces. It is ideal for slotting, profiling, and ramping operations in CNC manufacturing.

Product Features

- Specialized for Aluminum: The unique 3-flute design with a high helix angle (45°/55°) ensures rapid chip evacuation, preventing chip packing and built-up edge (BUE) common in soft materials.

- Mirror Polished Flutes: Cutting edges and flutes are highly polished to reduce friction and heat generation, ensuring a mirror-like finish on your workpiece.

- Premium Material: Made from Ultra-fine Micro Grain Tungsten Carbide (HRC55/HRC65), offering exceptional hardness and wear resistance.

- Corner Radius Design: The reinforced corner radius protects the cutting edge from breaking during high-feed machining, significantly increasing durability.

- High Precision: Ground with Swiss CNC grinding machines to ensure tight tolerances (h5/h6) for precision aerospace and mold making applications.

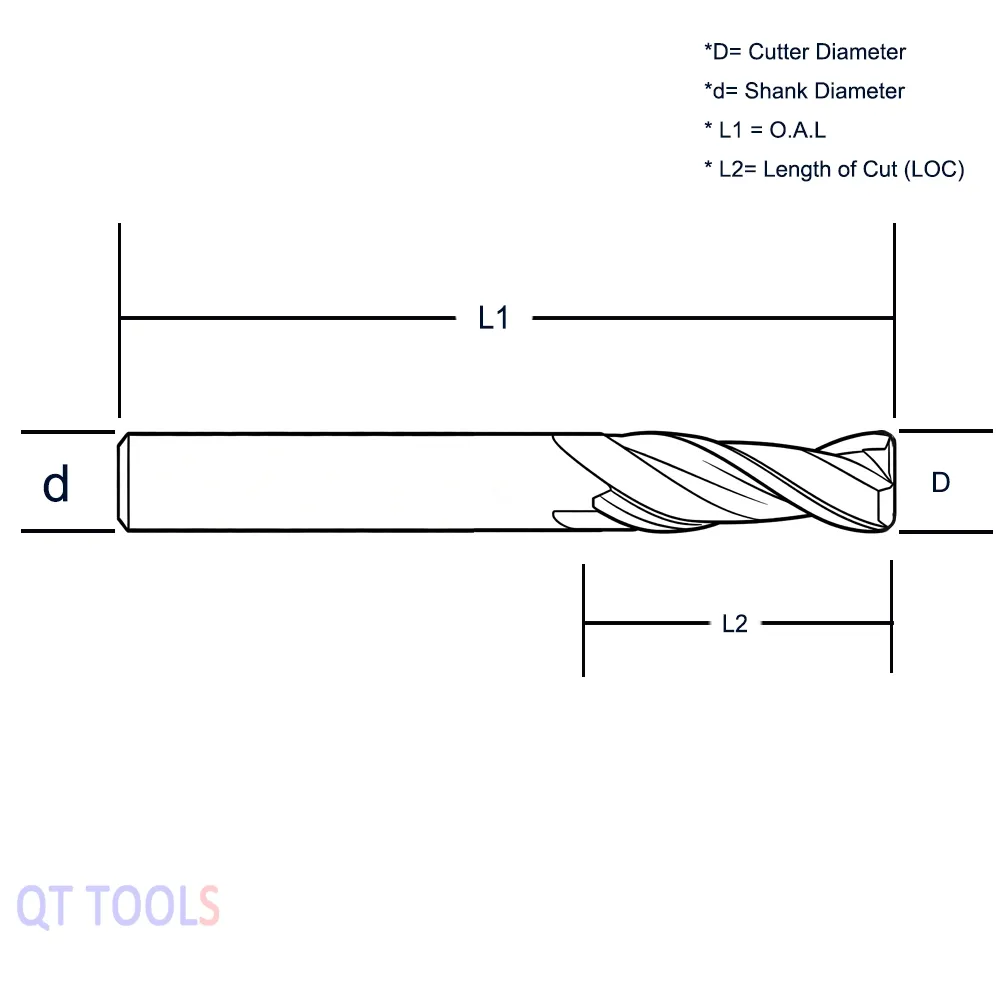

Specifications

All items listed below are In Stock and ready to ship.

(Note: Standard Corner Radii such as R0.2, R0.5, R1.0 are available. Please specify your required radius when ordering.)

RPM/Feed Reference (For Aluminum)

Recommended Cutting Parameters for Side Milling (ae=0.1D, ap=1.0D)

Note: Adjust parameters based on your machine rigidity, clamping stability, and specific aluminum grade (e.g., 6061 vs 7075).

Promotion Policy

We value our partnership. To support your business, we offer the following exclusive policies:

- Free Sample: We are confident in our quality. A Free Sample can be provided for testing if you agree to cover the shipping cost.

- First Order Coupon: New clients enjoy a **USD

50DiscountCoupon∗∗fortheirfirstorder(Minimumorderamount:USD

- Big Order Discount: Scale your production and save. Clients enjoy a 2% ~ 5% Discount for total order amounts exceeding USD $5,000.

Client Benefits

- Factory Direct: No middlemen. You get the best price directly from the manufacturer.

- Ready Stock: All specifications listed above are in stock, ensuring fast dispatch within 24-48 hours.

- Quality Assurance: 100% inspection before shipment. We use premium carbide rods to ensure consistent tool life.

- Global Shipping: We partner with DHL, FedEx, and UPS to deliver tools to your factory doorstep safely and quickly.

FAQ

Q: What is the standard corner radius for these end mills?

A: Our standard stock usually includes R0.2, R0.5, and R1.0 depending on the cutter diameter. Please contact sales to confirm the specific radius availability for your size.

Q: Can this tool cut steel?

A: This specific 3-flute design is optimized for Aluminum and non-ferrous metals. For steel machining, we recommend our 4-flute coated carbide end mills.

Q: Do you offer OEM/ODM services?

A: Yes! We can manufacture tools with custom dimensions, coatings, or laser-mark your logo on the shank.

Q: What is the lead time for bulk orders?

A: For stock items, we ship within 2 days. For very large orders (>5000 pcs) or custom tools, the production time is typically 7-10 days.