Spotting & Center DrillsReady to ShipIn-StockRecommended

2 Flute Solid Carbide Chamfer End Mill 60° 90° 120° - CNC Deburring & V-Groove Tool for Steel

Achieve smooth edge finishing with our 2 Flute Solid Carbide Chamfer End Mills. Perfect for deburring, chamfering, and V-grooving steel. Available in 60°, 90°, and 120° angles. High precision, AlTiN coated for durability. Get a free sample & bulk discounts!

Product Function

The 2 Flute Solid Carbide Chamfer End Mill is a versatile CNC milling tool designed primarily for edge profiling. Unlike spot drills, this tool is engineered for side milling operations. Its key functions include:

- Chamfering & Beveling: Creating uniform beveled edges on workpieces to remove sharp corners.

- Deburring: Efficiently removing burrs from machined edges in a single pass.

- V-Grooving: The 60° and 90° variants are excellent for cutting precise V-shaped grooves and lettering / engraving on steel surfaces.

- Countersinking: Capable of creating conical holes for screw heads.

Product Features

- 2-Flute Design: Large chip gullets allow for efficient chip evacuation, preventing clogging during high-speed side milling and grooving.

- High-Hardness Carbide: Made from premium Micro Grain Tungsten Carbide, ensuring the tool maintains a sharp edge even when machining tough alloy steels.

- Surface Coating: Coated with high-performance AlTiN (Aluminum Titanium Nitride), providing heat resistance and extending tool life in dry or wet machining.

- Multiple Angles: Available in 60°, 90°, and 120° to suit various drawing requirements (standard 45° chamfers use the 90° bit).

- Universal Shank: Most sizes feature a standard 4mm, 6mm, or 8mm shank for easy clamping in standard collets.

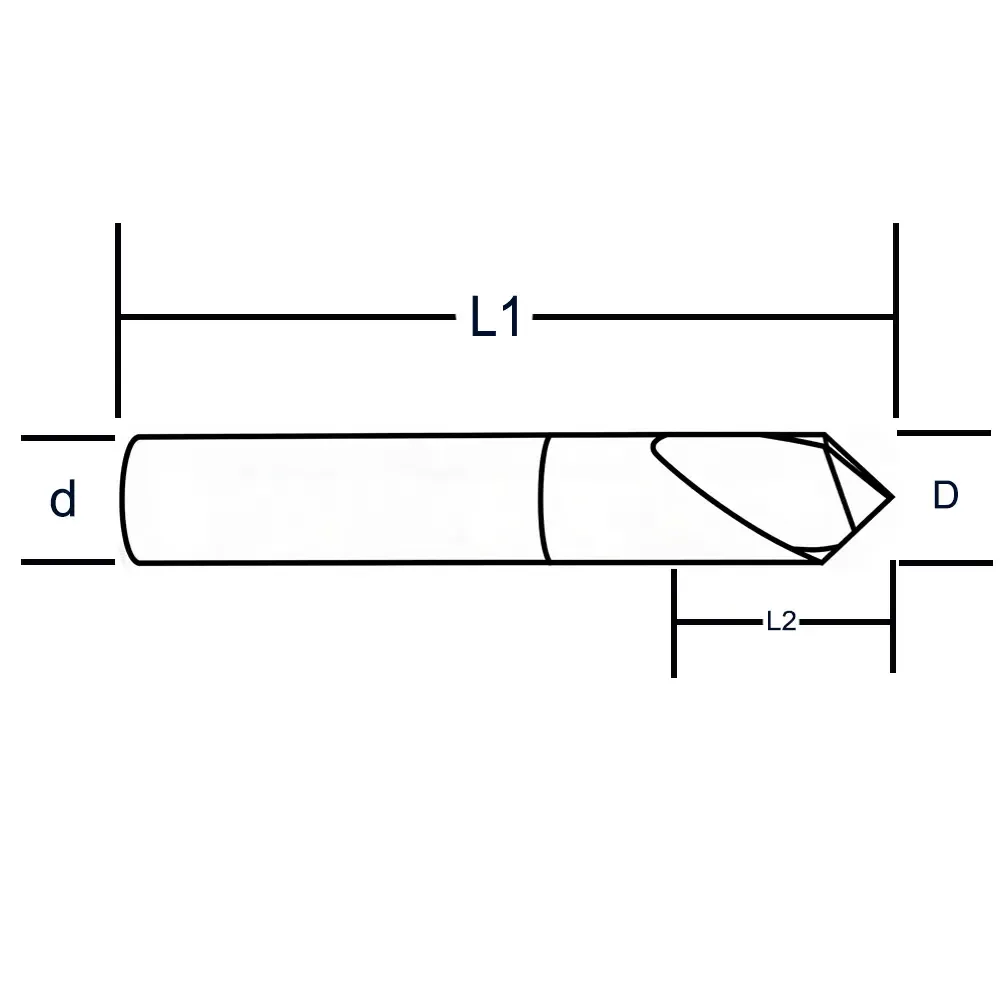

Specifications

60° Chamfer Mill Dimensions

90° Chamfer Mill Dimensions (Standard for 45° Chamfers)

120° Chamfer Mill Dimensions

RPM/Feed Reference (For Steel)

Target Material: Carbon Steel / Alloy Steel (HRC < 35)

Operation: Chamfering / Edge Profiling

Note: For chamfering, the effective cutting diameter is often smaller than the tool diameter. Please calculate RPM based on the effective diameter at the contact point for best results.

Promotion Policy

To help you reduce costs and test our quality, we offer the following policies:

- Free Sample: We provide free samples for testing! (Client pays shipping cost).

- First Order Coupon: New clients get a **

50USDdiscount∗∗ontheirfirstorderover

- Big Order Discount: Orders exceeding $5000 USD qualify for an additional 2%~5% discount.

Client Benefits

- One-Stop Shop: We manufacture both standard end mills and specialized chamfer tools, saving you sourcing time.

- Precision Guarantee: Our chamfer mills are ground on 5-axis CNC machines to ensure symmetric angles and consistent runout.

- Stock Availability: Most sizes listed above are in stock for immediate shipment via DHL/FedEx.

- Cost Efficiency: Direct factory pricing means you get premium carbide tools at a fraction of the big-brand cost.

FAQ

Q1: What is the difference between this Chamfer Mill and a Spot Drill?

A: A Spot Drill is optimized for vertical drilling (poking) to center a hole. A Chamfer Mill (this product) is optimized for lateral movement (milling) to machine edges or grooves. Chamfer mills generally have better chip clearance for side cutting.

Q2: If I need a 45° chamfer on my part, which tool do I buy?

A: You should purchase the 90° Chamfer Mill. A 90-degree V-shape creates a 45-degree angle relative to the flat surface.

Q3: Can I use this for engraving lettering?

A: Yes! The 60° and 90° tools are excellent for V-Carving and engraving text on steel, aluminum, and brass.

Q4: Is the tip sharp or flat?

A: Our standard chamfer mills come with a very small flat or radius at the tip to prevent chipping. If you need a needle-sharp point for micro-engraving, please specify "Engraving Bit" when ordering.