Product Function

The 2 Flute Micro Corner Radius End Mill (also known as a Bull Nose cutter) is the ultimate tool for precision mold making and micro-machining. It bridges the gap between square end mills and ball nose end mills:

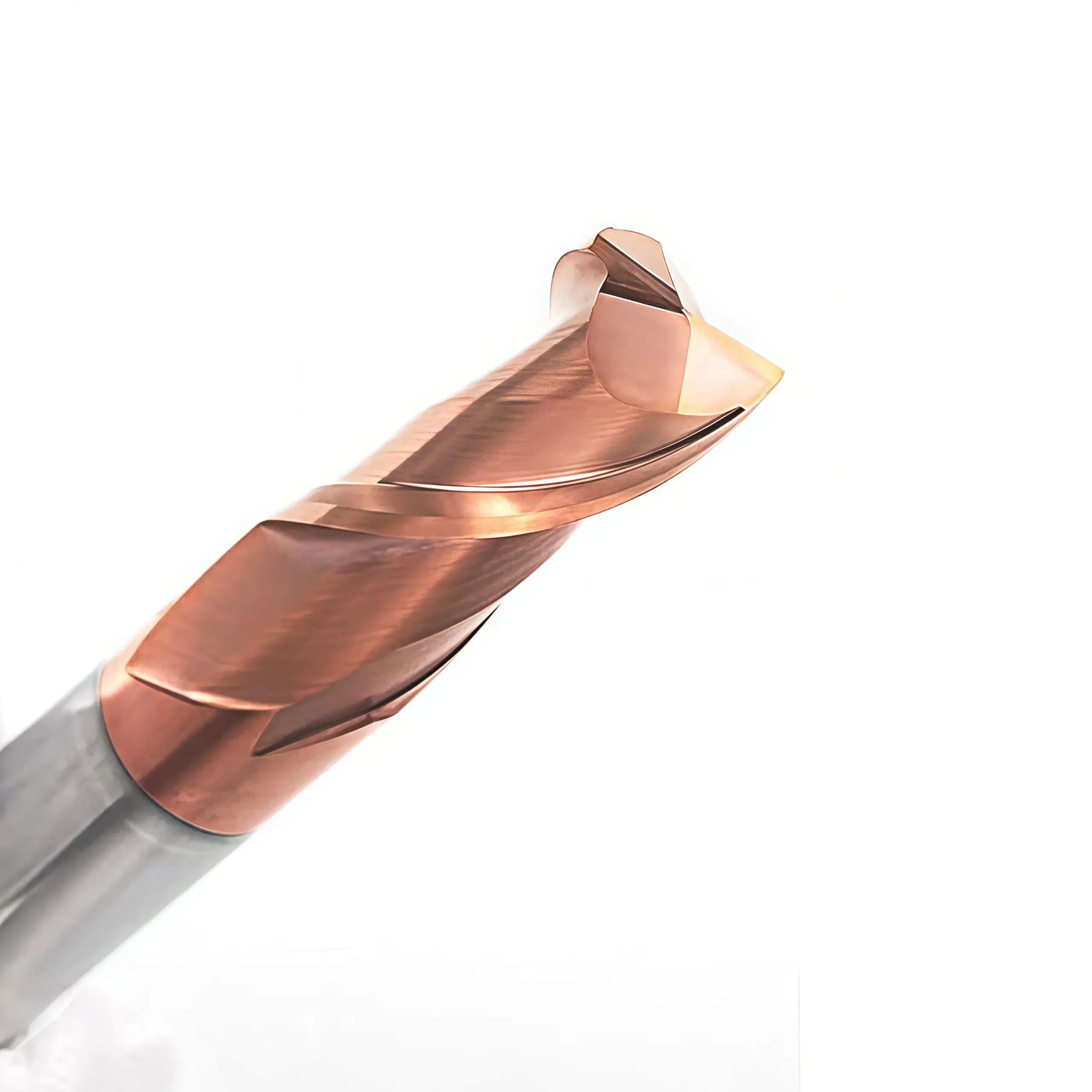

- Corner Strength: The corner radius (R) prevents the chipping often seen in sharp square end mills, significantly extending tool life in hard steel.

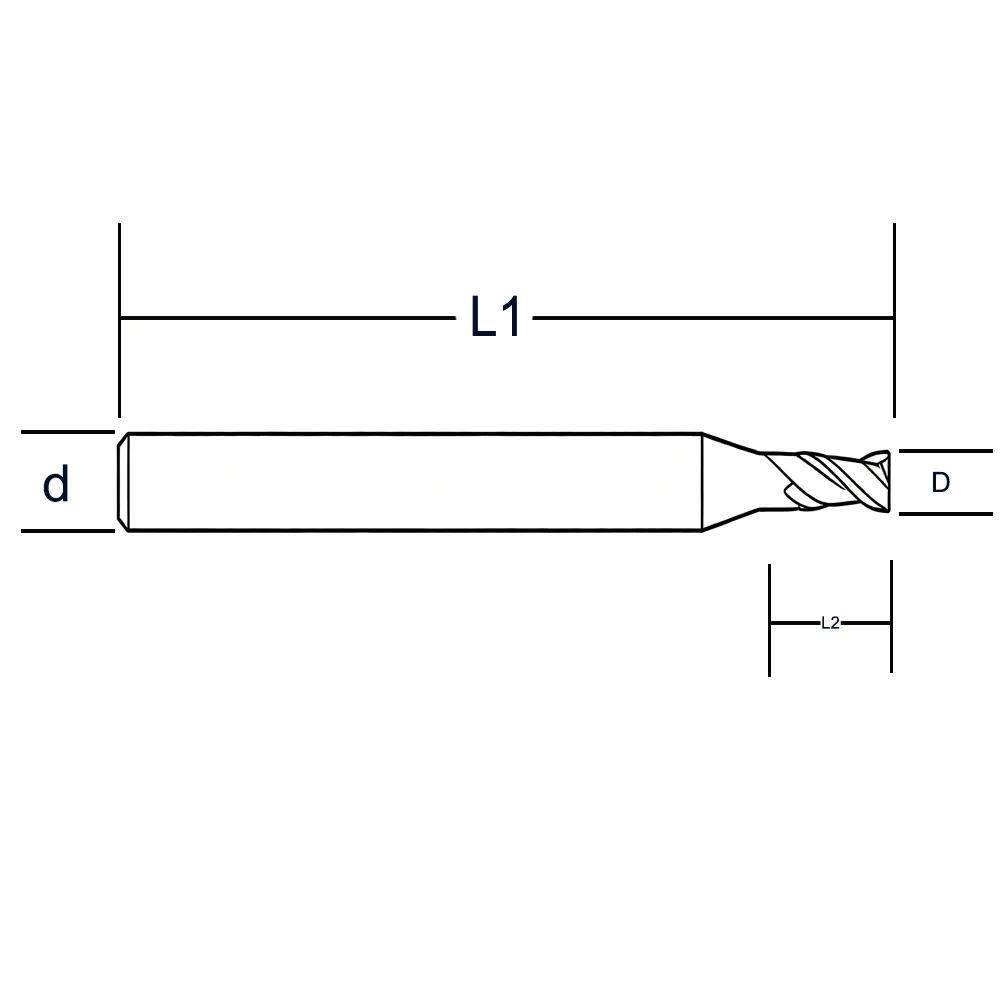

- Rib Processing: The "Long Neck, Short Flute" design allows the tool to reach into deep cavities and slots (ribs) without the shank rubbing against the workpiece.

- Flat Bottom Finishing: Unlike ball nose mills, it can machine flat bottoms efficiently while leaving a strong fillet at the corner.

Product Features

- Micro Precision: Available in ultra-precise diameters from 0.3mm to 1.5mm, including specific fractional sizes like 0.74mm/0.75mm for tight tolerance fittings.

- Rib Processing Geometry: Features a Stub Flute + Long Neck (Relief) design to maximize rigidity while allowing deep reach.

- Premium Material: Manufactured from Ultra-Fine Micro Grain Tungsten Carbide to withstand the high deflection forces common in micro-milling.

- Coating: Advanced AlTiN / TiSiN Coating provides extreme heat resistance and lubricity for machining Carbon Steel, Alloy Steel, and Mold Steel (up to HRC 55).

- Shank Accuracy: Standard h6 tolerance 4mm shank ensures perfect runout control, which is critical for preventing breakage in micro tools.

Specifications

Micro Corner Radius Series (Standard & Long Neck)

| | Effective Length / Neck (L3) | | |

|---|

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

Note: Standard Corner Radius (R) is typically 0.05R, 0.1R, or 0.2R depending on diameter. Please specify required Radius when ordering.

RPM/Feed Reference (For Steel)

Material: P20, NAK80, S136 (Mold Steel HRC 30-45)

*Note: Micro tools require high RPM and low runout (<0.005mm recommended).*

Promotion Policy

To support your precision mold making business, we offer:

- Free Sample: Test our micro precision risk-free. Free sample available (shipping cost applies).

- First Order Coupon: Get **

50USDOFF∗∗yourfirstorderover

- Mold Maker Discount: Specialized discount of 2%~5% for orders over $5000 USD.

Client Benefits

- Reduced Tool Breakage: The corner radius design is inherently stronger than sharp corner micro mills, saving you money on tool replacements.

- Deep Rib Access: Our "Long Neck" options (like the

ϕ1.0×2.5

- Precision Surface Finish: Excellent runout control ensures the walls of your mold cavities are smooth and accurate, reducing manual polishing time.

- Stock Availability: We keep stock of standard micro sizes to ensure your CNC machines never stop running.

FAQ

Q1: What is the benefit of a Corner Radius (Bull Nose) over a Square End Mill?

A: In micro sizes, the sharp corner of a square end mill is the weakest point and breaks easily. A corner radius adds material to this weak point, significantly increasing durability and tool life in hard steel.

Q2: What does "0.5+2.5" mean in the specification?

A: This refers to a "Long Neck" design. The actual cutting flute length is 0.5mm, but there is a relieved neck (slightly smaller diameter than the cutter) extending 2.5mm. This allows you to cut a slot 2.5mm deep without the shank rubbing, while keeping the tool rigid.

Q3: Can these cut hardened steel?

A: Yes, our coated series is suitable for steels up to HRC 55 (like NAK80, S136). For harder steels (HRC 60+), please contact us for our "Blue Series" High-Hardness tools.

Q4: What is the standard Radius (R) size?

A: For micro diameters (0.3-1.0mm), standard radius sizes are usually R0.05 or R0.1. We can customize specific radii based on your drawing requirements.