【inch】HRC 55 Carbide Aluminum End MILL 3 Flutes

1.High quality material of tungsten steel

2.Wear-resisting and Not easy to stick milling cutter

3.The blade by mirror grinding process

4.High efficiency of chip removal

5.Speed machining and High degree of smoothness

6.Strong and Continuous machining is not easy to break

7.Sharp sharp angle and precise front angle sharp sharp edge,Cutting design of 3 edge geometry.

1.High quality material of tungsten steel

2.Wear-resisting and Not easy to stick milling cutter

3.The blade by mirror grinding process

4.High efficiency of chip removal

5.Speed machining and High degree of smoothness

6.Strong and Continuous machining is not easy to break

7.Sharp sharp angle and precise front angle sharp sharp edge,Cutting design of 3 edge geometry.

Products Function

Material | Tungsten Cobalt Alloy, Tungsten Carbide | Machine Type | Milling Machine |

Controlling Mode | CNC Tooling System | Precision | 0.005-0.01mm |

Shank Diameter | 4-40mm | Coating | Coating |

Flute Diameter | 0.3-40mm | HRC | HRC55 |

Overall Length | 38-330mm | Suitable For | Aluminium and copper |

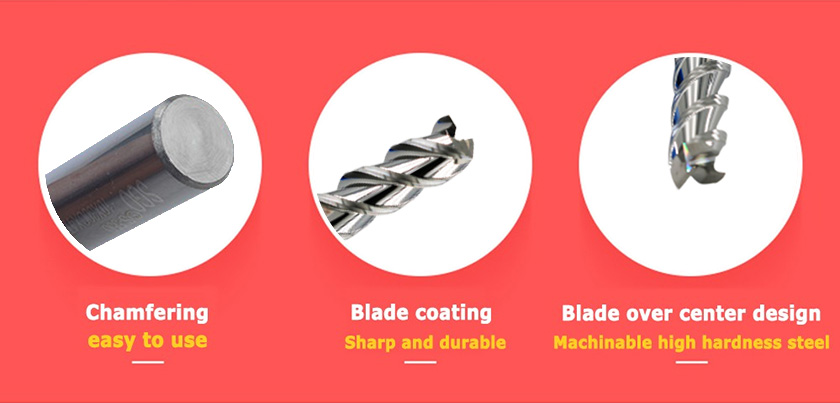

Products Features

1. Special Cutting Edge: Special cutting edge can increase the cutting ability. The lifetime of tools and machines will be longer

2. Smooth And Wide Flute: Smooth and wide flute will remove the cuttings more easily

3. High Quality Raw Material: The raw material is used of high toughness, grain-sized carbon tungsten

4. Polished Surface Treatment: With high polished surface treatment, reduce the friction coefficient could be reduced, the lathe efficiency could be improved, more production time could be saved

Specitications

Standard type

Model No. | Flute Diameter (mm) | Flute length (mm) | Shank Diameter (mm) | Overall length (mm) |

D1*3*D4*50 | 1 | 3 | 4 | 50 |

D1.5*4.5*D4*50 | 1.5 | 4.5 | 4 | 50 |

D2*6*D4*50 | 2 | 6 | 4 | 50 |

D2.5*7.5*D4*50 | 2.5 | 7.5 | 4 | 50 |

D3*9*D4*50 | 3 | 9 | 4 | 50 |

D3.5*10*D4*50 | 3.5 | 10 | 4 | 50 |

D4*12*D4*50 | 4 | 12 | 4 | 50 |

D5*15*D6*50 | 5 | 15 | 6 | 50 |

D6*18*D6*50 | 6 | 18 | 6 | 50 |

D8*24*D8*60 | 8 | 24 | 8 | 60 |

D10*30*D10*75 | 10 | 30 | 10 | 75 |

D12*35*D12*75 | 12 | 35 | 12 | 75 |

D14*45*D14*100 | 14 | 45 | 14 | 100 |

D16*50*D16*100 | 16 | 50 | 16 | 100 |

D18*50*D18*100 | 18 | 50 | 18 | 100 |

D20*50*D20*100 | 20 | 50 | 20 | 100 |

Extra Length Type

Model No. | Flute Diameter (mm) | Flute length (mm) | Shank Diameter (mm) | Overall length (mm) |

D4*16*D4*75 | 4 | 16 | 4 | 75 |

D4*20*D4*100 | 4 | 20 | 4 | 100 |

D6*24*D6*75 | 6 | 24 | 6 | 75 |

D6*35*D6*100 | 6 | 35 | 6 | 100 |

D8*35*D8*75 | 8 | 35 | 8 | 75 |

D8*40*D8*100 | 8 | 40 | 8 | 100 |

D10*40*D10*100 | 10 | 40 | 10 | 100 |

D12*45*D12*100 | 12 | 45 | 12 | 100 |

D6*45*D6*150 | 6 | 45 | 6 | 150 |

D8*50*D8*150 | 8 | 50 | 8 | 150 |

D10*60*D10*150 | 10 | 60 | 10 | 150 |

D12*60*D12*150 | 12 | 60 | 12 | 150 |

D14*70*D14*150 | 14 | 70 | 14 | 150 |

D16*70*D16*150 | 16 | 70 | 16 | 150 |

D18*70*D18*150 | 18 | 70 | 18 | 150 |

D20*70*D20*150 | 20 | 70 | 20 | 150 |

Show Details

Clients Benefits:

1. More revenue: due to our big stocks, tools cost can be controlled. With our competitive price, we can help you to make even more revenue but with lower cost.

2. No quality complain: By control quality from raw material to production process and 100% examed before shipment, so we can help you to keep away from any clients complain for quality issue.

3. One stop shop service: we have variety of cnc milling tools, cnc router bits and cnc drilling tools. You do not need to buy everywhere and pay shipping cost everywhere.

4. Increase clients conversion rate: with our technical and market experience, we can help you to generate more customer with even higher conversion rate.

5. Fast feedback: we offer 24 hours online service, any questions from you or your clients will be replied immediately, your clients will be happy, then you will be happy.

6. Cutomized tools: Customized tools can be provided acccording to your drawing and your work piece.